Do I need to wear accessories when using power tools?

The Importance of Accessories and Proper Equipment for Safety with Power Tools

When embarking on DIY projects or home improvements, power tools can be invaluable assets, transforming ordinary tasks into streamlined workflows. However, engaging with power tools comes with inherent risks. Therefore, understanding the vital role that accessories and appropriate equipment play is essential for safeguarding both the user and the surrounding environment. This comprehensive overview will delve into the various aspects of safety associated with power tools, outlining the must-have equipment and accessories that can mitigate hazards and significantly enhance the user experience.

Understanding the Risks of Power Tools

Power tools, whether used in a professional workshop or for home improvement projects, can pose various risks. Common hazards include cuts, electrical injuries, and even serious accidents if tools are misused. According to the U.S. Bureau of Labor Statistics, injuries associated with power tools can range from minor cuts to severe injuries requiring extensive medical intervention. Therefore, awareness of these dangers is the first step towards fostering a culture of safety around power tools.

The Role of Accessories in Enhancing Safety

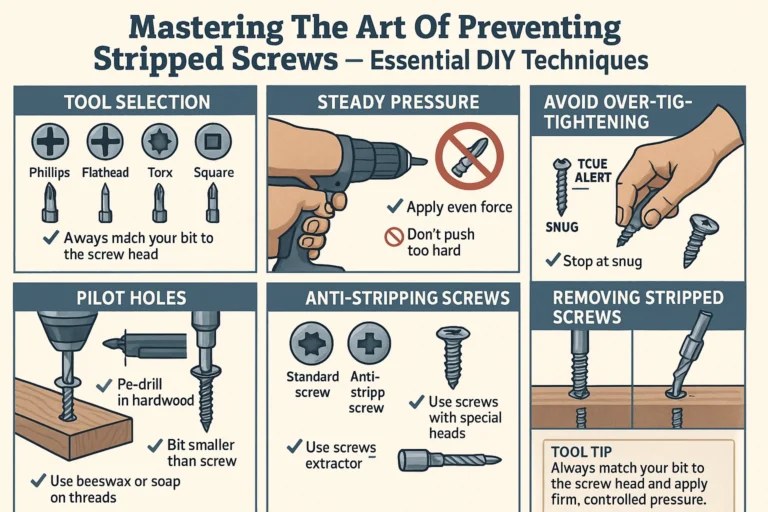

Accessories for power tools play a pivotal role in mitigating risks and ensuring a safe working environment. Here’s a closer look at some essential accessories that should be included in any toolkit.

1. Personal Protective Equipment (PPE)

One of the most crucial aspects of power tool safety is the use of Personal Protective Equipment (PPE). Essential items include gloves, goggles, ear protection, and dust masks. Each component serves a specific purpose:

- Gloves protect against cuts and abrasions while handling tools or materials.

- Goggles shield the eyes from flying debris and sawdust.

- Ear protection is vital for safeguarding against hearing damage from loud machinery.

- Dust masks reduce the inhalation of harmful dust particles.

Before starting any project, ensure that you have the appropriate PPE tailored to the power tool you intend to use.

2. Power Tool Guards

Most modern power tools come equipped with safety guards designed to protect the user from accidental contact with moving parts. For instance:

- Table saws have blade guards that can minimize the chance of injury.

- Circular saws feature guards that retract during operation, reducing the risk of cutting oneself.

Always check that these guards are in good working order and ensure that they are used as intended during operation.

3. Safety Switches and Features

Many power tools include built-in safety switches or features meant to prevent accidental starts. To ensure your safety:

- Familiarize yourself with the specific lock-out mechanisms of your tools.

- Ensure that trigger locks are fully functional and utilized correctly.

These features can be pivotal in preventing inadvertent accidents, especially in environments with multiple users.

4. Extension Cords and Power Strips

When working with power tools, ensuring that you have the right type of extension cords is essential. Using cords rated for the tool’s power requirement can prevent overheating and electrical hazards. Always opt for:

- Three-pronged cords that reduce the risk of electric shock.

- Heavy-duty cords suitable for outdoor use that provide extra safety against environmental elements.

5. Workbenches and Clamps

A stable workspace is vital for safe tool use. Utilizing sturdy workbenches and clamping tools can help secure your workpieces, which in turn reduces movement and the chance of accidents. Consider the following:

- Adjustable workbenches can accommodate various projects and ensure a secure surface.

- Clamps can secure wood or materials in place while using power tools, providing greater stability.

Setting Up a Safe Work Environment

The workspace you create plays a significant role in the overall safety of power tool usage. Here are some best practices to ensure your environment is conducive to safe work:

1. Adequate Lighting

Proper visibility is fundamental when using power tools. Ensure that your workspace is well-lit to minimize the risk of errors and accidents. Consider using:

- Bright overhead lights

- Task lights for focused illumination on the workpiece

2. Organized Space

Clutter can lead to accidents. Keep tools and materials organized, and store items you aren’t using out of the way to maintain a tidy workspace. Implement systems like:

- Tool racks for easy accessibility and storage.

- Labeling systems for materials that help in quick identification and retrieval.

3. Ventilation

Some power tools can create dust or fumes that could be detrimental to health. A well-ventilated area reduces inhalation risks. Whenever possible, work outdoors or use fans and exhaust systems to improve air circulation.

Best Practices for Using Power Tools

Beyond accessories, establishing safe working habits is crucial for preventing accidents. Here are several essential practices:

1. Read Instruction Manuals

Before you use any power tool, take the time to read the instruction manual. Familiarizing yourself with the tool’s features and safety guidelines is essential for ensuring proper usage.

2. Maintain Tools Regularly

Regular maintenance of power tools is vital for their performance and safety. This includes:

- Checking for frayed cords or faulty switches

- Sharpening blades and replacing worn parts

- Cleaning tools after use to prevent malfunction

3. Stay Focused

Avoid distractions while using power tools. Wearing earbuds or allowing interruptions can divert attention and lead to accidents. Maintaining focus is key.

4. Use Proper Techniques

Employing the right techniques when using power tools can significantly reduce the risk of injury. For example, always cut away from your body, use two hands when operating powerful tools, and maintain a balanced stance to ensure stability.

5. Don’t Rush

Taking your time reduces the risk of mistakes that can lead to injuries. Always work at a steady pace and avoid the temptation to rush through tasks, especially if you’re tired or distracted.

Emergency Preparedness

No matter how well-prepared you are, accidents can happen. Being ready for emergencies is just as crucial as preventing them. Consider the following:

1. First Aid Kits

Always have a fully stocked first aid kit readily available in your workspace. Items should include bandages, antiseptic wipes, a splint, and other essential items to treat minor injuries.

2. Emergency Contact Information

Keep emergency contact information posted visibly in your workspace. This should include local emergency services, medical facilities, and your contacts.

3. Emergency Exits

Know your surroundings and understand the quickest routes to exit in case of an emergency. Ensure that these exits are unobstructed and readily accessible.

In conclusion, using power tools can transform your DIY projects from mundane tasks into creative expressions, but safety should always be a top priority. By investing in the right accessories and ensuring a safe working environment, you can drastically reduce your risk of accidents. From wearing protective gear to maintaining your tools, each step plays a critical role in safeguarding your wellbeing.

Essential Protective Gear for Power Tool Safety: Your Ultimate Guide

Safety should always be a top priority when working with power tools. Whether you’re a DIY enthusiast or a seasoned professional, understanding the various protective accessories available can significantly minimize the risk of injury. This guide offers a detailed examination of essential protective gear necessary for safe operation while using power tools, covering items such as protective eyewear, hearing protection, respiratory gear, gloves, protective clothing, and appropriate footwear.

The Importance of Protective Eyewear

When working with power tools, your eyes are vulnerable to debris, sparks, and intense light. Protective eyewear is crucial for shielding your eyes from potential hazards. There are two primary types of safety glasses: those that shield against impact and those that filter harmful light.

- Safety Glasses – Impact-resistant safety glasses are essential for tasks that involve flying debris, such as sanding, cutting, or drilling. Always ensure that your safety glasses meet the standards set by regulatory bodies like ANSI (American National Standards Institute) or OSHA (Occupational Safety and Health Administration).

- Safety Goggles – For tasks that generate dust or require additional facial coverage, goggles are the preferred choice. They create a tight seal around your eyes and provide an extra layer of protection.

Key Features to Look For:

- Anti-fog Coating – Reduces fogging during prolonged use.

- Scratch Resistance – Increases durability, maintaining clear vision.

- UV Protection – Important for outdoor work to protect against harmful rays.

Hearing Protection: Don’t Overlook the Noise

Power tools can be significantly loud, and prolonged exposure to high decibel levels can lead to irreversible hearing damage. Employing hearing protection is essential to safeguarding your auditory health.

- Earplugs – These are a convenient option that fits snugly in the ear canal, effectively reducing noise levels. They come in disposable and reusable varieties and can frequently provide a high degree of noise reduction.

- Earmuffs – For those who prioritize comfort, earmuffs offer a cushioned fit that encases the entire ear. Many earmuffs are equipped with adjustable headbands, ensuring a secure fit.

Noise Reduction Rating (NRR) – When selecting hearing protection, pay attention to the NRR – it indicates how much noise is blocked or reduced. The higher the NRR, the more effective the protection.

Respiratory Protection: Breathing Easy

Dust, fumes, and other airborne particles can pose serious health risks. Depending on the tasks at hand, different types of respiratory protection may be necessary.

- Dust Masks – These offer a basic level of protection against non-toxic dust and are appropriate for light woodworking or sanding.

- Respirators – When working with hazardous materials or in enclosed spaces, a half-mask or full-face respirator might be required. These devices filter out harmful particles and protect the wearer from fumes and vapors.

Choosing the Right Respiratory Gear: When selecting respiratory gear, always assess the level of exposure and follow specifications outlined by safety guidelines. Ensure the mask fits well to create a proper seal and enhances comfort for extended wear.

The Role of Gloves in Tool Safety

Gloves are another critical component of your protective gear. These can guard against cuts, abrasions, and other injuries that could arise while handling power tools.

- Cut-resistant Gloves – If you’re working with sharp tools, opt for gloves specifically designed for cut protection. These often include materials like Kevlar or Dyneema.

- General-purpose Gloves – Suitable for handling tools and materials but make sure they don’t lose grip while using power tools.

Important Considerations:

- Sizing and fit: Gloves should fit snugly but not be too tight, allowing for complete dexterity.

- Material: The glove material should match the task. For instance, leather gloves are excellent for heat resistance, while nitrile gloves offer better chemical resistance.

Protective Clothing: Dress for Success

Your clothing is another line of defense against potential injuries while using power tools. Proper protective clothing is essential to keep you safe and comfortable.

- Long Sleeves and Trousers – Wearing long sleeves and long pants helps protect your skin from cuts and scrapes. Fabrics such as denim or heavier canvas are great choices, as they offer increased durability.

- Flame-resistant Clothing – If you’re working with highly flammable materials or equipment, consider garments made from flame-resistant materials.

- High-visibility Clothing – If you’re working in environments with moving machinery or vehicles, wearing high-visibility clothing can enhance your safety by making you more noticeable.

Choosing the Right Footwear

Footwear is often an overlooked aspect of protective gear, but it is integral to your overall safety. Proper footwear should provide support, slip resistance, and protection against punctures.

- Steel-toe Boots – These are essential for protection against falling objects. They safeguard your toes and provide additional stability, making them a wise choice for any power tool work.

- Slip-resistant Soles – Boots with slip-resistant surfaces can prevent accidents in workplaces where spills may occur.

- Comfort and Fit – The right footwear should not only protect you but also provide comfort during long hours of work.

Conclusion: Equip Yourself for Safety

When it comes to using power tools, being prepared and properly equipped with protective accessories is essential. From eyewear to footwear, each piece of safety gear plays a vital role in minimizing risks and ensuring a productive working atmosphere. By prioritizing safety and investing in high-quality protective gear, you can focus on your project while knowing you’re protected against potential hazards.

Always strive to stay informed about the latest safety guidelines and gear updates. This not only enhances your safety but also promotes a culture of safety in DIY and professional work environments. Stay safe, and happy tool usage!

The Essential Guide to Power Tool Safety: A Priority for Everyone

When it comes to using power tools, prioritizing safety is essential—not just for seasoned professionals but for DIY enthusiasts and occasional users alike. Whether you’re building a new deck, revamping your home, or tackling minor repairs, ensuring your safety and the safety of those around you should always come first. In this guide, we’ll discuss why power tool safety is paramount and offer practical tips on how to maintain safe practices while using these powerful devices.

Understanding the Importance of Safety

Power tools are a great asset for speeding up tasks and achieving precise results. However, they can pose substantial risks if not handled correctly. Accidents can lead to severe injuries, property damage, or even fatalities. Therefore, maintaining a strong focus on safety is crucial.

Regardless of your experience level—whether you are an expert tradesperson or an occasional DIYer—mistakes and accidents can happen. Therefore, adopting a safety-first mindset is not just advisable; it’s necessary to minimize risks and foster a safe working environment.

Essential Accessories for Safety

A variety of accessories exist solely to enhance safety when operating power tools. Here are some crucial items that you should consider acquiring:

- Personal Protective Equipment (PPE): Basic PPE includes safety goggles, ear protection, gloves, and dust masks. These items shield you from debris, excessive noise, and harmful particles.

- Tool Guards and Safety Switches: Many power tools come equipped with safety guards or features such as automatic shutoff mechanisms. Familiarize yourself with these elements and ensure they function correctly before use.

- Extension Cords and Power Strips: Use quality extension cords and power strips designed for high-power tools. Ensure they have overload protection and are in good condition to prevent electrical accidents.

Proper Operating Procedures

Following established procedures is critical to maintaining safety when working with power tools. Here are some key practices to keep in mind:

- Read the Manual: Before using any tool, read through the manufacturer’s manual. Understanding the functionalities and proper operating procedures can help you use the tool safely and effectively.

- Inspect Your Tools: Always inspect tools before beginning a project. Check for any signs of wear and tear, loose parts, or damage. If you notice anything unusual, do not attempt to use the tool until it has been repaired or replaced.

- Use Tools for Their Intended Purposes: Each power tool is designed for specific tasks. Using a tool outside its intended purpose increases the risk of malfunction, accidents, and injuries. Make sure to follow guidelines for optimal use.

- Stay Focused: When working with power tools, distraction can lead to accidents. Avoid multitasking; keep your attention on the work and remain aware of your surroundings.

Maintenance: A Key Component of Safety

Proper maintenance of your power tools is vital for safe usage. Neglecting maintenance can lead to equipment failure, which can create hazardous situations. Here are some tips for maintaining your tools:

- Regular Cleaning: After each use, clean your tools to keep them in good working condition. Remove dust, debris, and sawdust to prevent blockages and ensure smooth performance.

- Sharpening Blades and Bits: Dull blades and bits can cause tools to malfunction or operate inefficiently, leading to accidents. Regularly sharpen these components to maintain optimal cutting performance.

- Battery Maintenance: If you’re using battery-operated tools, ensure that the batteries are charged and stored properly. Follow the manufacturer’s guidelines for battery care to prolong their lifespan and maintain effectiveness.

- Professional Servicing: For complex tools or those used frequently, consider having them serviced by a professional. Annual check-ups can identify potential issues before they become serious problems.

Training and Learning: Stay Updated

Continuous education on power tool safety is essential. As technology evolves, new tools and features emerge. Ensure you are well-informed about advancements in power tools:

- Online Resources: Websites like One Power Tool provide a wealth of information on best practices, safety tips, and ways to handle common challenges when using power tools.

- Hands-on Workshops: Attend workshops or safety courses to develop your skills. Learning from experienced professionals can provide essential insights into safe tool handling.

- Feedback and Community: Engage with other DIY enthusiasts or professionals. Sharing experiences can highlight common mistakes and effective practices, making you a safer and more knowledgeable user.

Creating a Safe Work Environment

An organized and well-maintained workspace significantly influences safety. Here are some tips to create a safe environment while using power tools:

- Clear the Area: Ensure your work area is tidy and devoid of unnecessary clutter. This minimizes the chances of tripping or encountering obstacles while operating tools.

- Proper Lighting: Ensure your workspace is well-lit to enhance visibility, thus permitting you to notice potential hazards promptly.

- Set Boundaries: If working in a shared space, establish clear boundaries to keep others at a safe distance while operating power tools.

- Keep First-Aid Supplies Handy: Accidents can happen despite your best efforts. Implement a first-aid kit in your workspace and familiarize yourself with its contents and basic emergency procedures.

In Conclusion

Safety when using power tools should always be your highest priority, regardless of your experience or skill level. By implementing the right accessories, following proper procedures, and maintaining your tools, you can significantly reduce the risk of accidents. Furthermore, continually updating your knowledge and maintaining a safe work environment will ensure that every project is completed safely and effectively.

Don’t overlook the importance of power tool safety—make it an essential part of your DIY journey!