Why is it important to follow occupational safety standards when using power tools?

The Critical Role of Power Tools in Modern Industries: Navigating Safety Standards

When we look around at the world of construction, manufacturing, and even DIY home projects, power tools play an undeniable role in shaping efficiency, quality, and productivity. These tools have revolutionized how work gets done, allowing tasks that previously took hours or days to be completed in a fraction of the time. However, with this convenience comes the responsibility to ensure safety in their operation. In this article, we will explore the importance of power tools, their diverse applications in various industries, and the crucial safety protocols that should guide their usage. [Source]

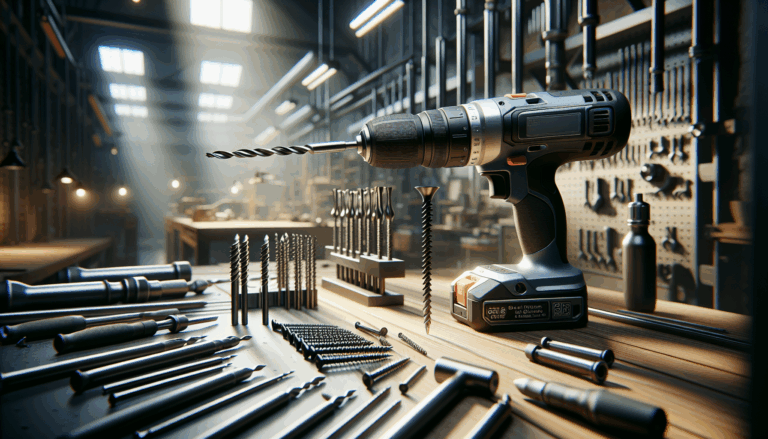

The Power Tool Landscape

Power tools have dramatically changed the landscape of manual labor and craftsmanship. They encompass a wide range of equipment, from drills and saws to sanders and grinders, each designed to facilitate specific tasks and improve performance. Whether in a high-paced industrial environment or a home workshop, power tools provide the force and precision needed to execute complex tasks efficiently.

In the construction industry, for instance, power tools help crew members cut down on the time it takes to nail frames, construct walls, or finish surfaces. Similarly, in manufacturing, tools like electric saws and machinery enable operators to maintain consistent production standards, thereby enhancing quality. [Source]

Industries Relying on Power Tools

The influence of power tools extends across various sectors. Here are a few notable industries where power tools are essential:

- Construction and Renovation: Professionals rely on electric drills, saws, and sanders to complete building tasks efficiently. From framing to finishing, the right power tool can make all the difference.

- Manufacturing: Power tools are crucial in factories for assembly lines and machine operation, enabling precise movements and ensuring high-quality production.

- Automotive Repair: Mechanics utilize power tools like impact wrenches and electric screwdrivers to perform repairs quickly and accurately, simplifying tasks and reducing physical strain.

- Home Improvement: DIY enthusiasts embrace power tools for various home projects, such as building furniture and home renovations. Tools like power saws and nail guns allow homeowners to achieve professional results.

- Crafting and Woodworking: Crafters use power tools for fine detail work and complex projects, with equipment like routers and sanders enhancing craftsmanship.

The Necessity of Safety Standards

Despite the myriad benefits that power tools offer, the risks associated with their use are also significant. A lack of knowledge regarding the operation or disregard for safety protocols can result in serious injuries. Consequently, adhering to safety standards is not merely an option; it is an absolute necessity.

Key Power Tool Safety Protocols

To mitigate risks and ensure a safe working environment, here are some critical safety protocols every user should follow:

- Read User Manuals: Familiarizing oneself with the manual for each power tool is essential.

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE, such as goggles, gloves, and ear protection.

- Inspect Tools Before Use: A pre-use inspection can prevent many accidents.

- Maintain Proper Work Areas: Keep work areas clean and organized.

- Use Tools as Intended: Each tool is designed for specific applications.

- Keep Hands and Clothing Clear: Secure loose clothing and long hair away from moving parts.

- Understand Emergency Procedures: Familiarize yourself with emergency protocols.

- Educate and Train: Continuous training on power tool safety should be part of the workplace culture.

Conclusion

As we embrace the capabilities of power tools, it is crucial to remember that safety and functionality go hand in hand. By adhering to established safety protocols, individuals and organizations can harness the benefits of these tools while minimizing risks to health and well-being. Let’s maintain safe environments that foster both efficiency and security in our projects.

Safeguarding Against Hazards: The Importance of Occupational Safety Standards in Power Tool Use

Power tools are fundamental in both DIY endeavors and professional settings, offering incredible efficiency and speed. However, this efficiency comes with a risk factor that cannot be overlooked. Following occupational safety standards is crucial to protect users from potential injuries and accidents when working with power tools. [Source]

Understanding the Risks of Power Tool Usage

Every power tool carries inherent risks, ranging from minor injuries to life-threatening situations. Some common risks include:

- Cuts and Lacerations: Open blades and rotating parts.

- Electrical Hazards: Faulty wiring or moisture causing shocks.

- Projectiles: Tools launching parts or debris.

- Hearing Damage: Loud machinery causing permanent loss.

- Respiratory Issues: Dust and fumes causing health problems.

Recognizing these dangers is the first step toward creating a safer work environment.

Key Safety Standards to Implement

1. Use Personal Protective Equipment (PPE)

PPE is paramount; it protects against potential injuries. Essential items include safety glasses, ear protection, gloves, and steel-toed boots.

2. Regular Maintenance and Inspection of Tools

Conduct routine checks to ensure tools function properly and safely.

3. Proper Usage Techniques

Always familiarize yourself with the manufacturer’s instructions and use tools for their intended purpose.

4. Maintain an Organized Workspace

Keep work areas tidy to minimize distractions and prevent accidents.

5. Follow Electrical Safety Protocols

Utilize Ground Fault Circuit Interrupters (GFCIs) and avoid wet conditions when operating electrical tools.

Cultivating a Safety Culture

Implementing regular safety workshops and communication channels for reporting unsafe conditions fosters a culture of safety. [Source]

The Role of Manufacturers

Manufacturers have a responsibility to enhance safety through designs that incorporate automatic shut-offs and safety guards.

Conclusion

By adhering to occupational safety standards, users can significantly minimize risks associated with power tools, safeguarding both themselves and others in the work environment.

Emphasizing Collective Responsibility in Safety Standards

The importance of safety while using power tools extends to collective responsibility, ensuring the safety of the operator and bystanders alike. Following safety standards contributes to a protective barrier for everyone involved. [Source]

Understanding Safety Standards

Safety standards are essential guidelines that help mitigate risks associated with power tool operation.

1. Establishing Protocols

These protocols clarify safe tool operation.

2. Risk Assessments

Conduct assessments to identify hazards before beginning a project.

3. Training and Education

Proper training is vital for tool operation safety.

Collective Responsibility

Creating a culture of safety involves all individuals, from operators to supervisors and bystanders. Each has a role to play in maintaining a safe environment.

Conclusion

Safety while using power tools requires a collective commitment in any workspace. By prioritizing adherence to safety standards, we create an environment less prone to accidents.

Mastering Power Tool Safety: Protecting Property and Enhancing DIY Success

Embarking on a DIY project can be exciting, yet it requires safety to safeguard both personal wellbeing and property. This article outlines the primary risks and essential safety practices associated with power tool usage. [Source]

The Risks Posed by Power Tools

Improper handling of power tools can lead to physical injuries and property damage. Key risks include cuts, electrical hazards, and improper usage.

Essential Safety Practices for Power Tool Utilization

1. Read the Equipment Manual

Familiarizing yourself with the tool’s manual is essential for safety.

2. Select the Appropriate Tool

Using the right tool minimizes the likelihood of accidents.

3. Wear Protective Equipment

PPE should include safety goggles and gloves.

4. Maintain an Organized Workspace

Clutter can lead to distractions and accidents.

5. Conduct Pre-Operational Inspections

Check tools for wear, ensuring they function safely.

6. Adhere to Electrical Safety Practices

Prioritize safety when using electric-powered tools.

Preparing for Emergencies

Always have a first aid kit accessible, and know emergency contacts. [Source]

Conclusion

Prioritizing safety when using power tools leads to more successful DIY projects without property damage. Embrace best practices to enjoy your home improvement tasks.

Safeguarding Your Power Tools: Why Safety Practices Matter

Neglecting safety protocols with power tools can lead to injuries and expensive repairs. This article discusses the importance of following safety guidelines for tool longevity. [Source]

Recognizing the Risks of Power Tools

Mishandling tools can cause severe injuries. Regular maintenance and adhering to safety practices are crucial.

Advantages of Following Safety Guidelines

Safety guidelines enhance operational efficiency and extend tool lifespan.

Best Practices for Power Tool Safety

- Follow Manufacturer Instructions

- Regular Maintenance Inspections

- Select the Right Tool for the Job

- Safeguard Your Work Area

- Stay Focused

Conclusion

Establishing and adhering to safety protocols not only protects users but also prolongs the life of your tools. By committing to safe practices, you can tackle projects with confidence.

Navigating the Legal Landscape of Safety Standards for Power Tools

Understanding the legal implications of safety standards in power tool use safeguards individuals and businesses alike. It’s vital for compliance and avoiding legal trouble. [Source]

The Importance of Safety Standards

Safety standards minimize the risks of accidents and injuries. Compliance is not just advisable; it is often legally mandated.

1. Protection of Lives

Prioritizing safety reduces the risk of serious accidents.

2. Legal Necessity

Compliance with safety regulations is essential to avoid legal ramifications.

3. Insurance Compliance

Insurance companies often require adherence to safety standards for coverage.

Consequences of Neglecting Safety Regulations

Non-compliance can lead to fines, increased legal liability, and reputational damage.

Ensuring Compliance with Safety Standards

Developing a safety-focused culture requires ongoing education, routine audits, and creating a reporting culture.

Conclusion

Grasping the legal implications tied to safety standards is crucial for operational integrity. Prioritizing safety protects lives and businesses alike.

Comprehensive Power Tool Safety Tips for a Secure Workspace

Ensuring safety while using power tools is essential for preventing accidents. Here are some practical guidelines to foster a secure working environment. [Source]

1. Equip Yourself with Personal Protective Gear

PPE acts as your first line of defense against hazards.

2. Conduct a Thorough Pre-Operation Inspection

Check tools and workspace to identify potential hazards.

3. Use Tools Correctly and Safely

Adhere to the user instructions and safety practices.

4. Be Aware of Your Surroundings

Maintain a tidy workspace and communicate with others nearby.

5. Prioritize Electrical Safety

Use GFCIs and ensure dry conditions when operating electric tools.

6. Maintain and Store Tools Properly

Regular maintenance prolongs tool life and ensures safety.

7. Be Prepared for Emergencies

Keep first aid kits and know emergency contacts for swift responses.

8. Offer Training and Supervision

Providing thorough training can mitigate power tool risks.

Conclusion

Overall, prioritizing safety when it comes to power tools can vastly reduce the risk of accidents. Implement these practices to enjoy safer and more productive projects.

Sources

- Example Publisher – The Critical Role of Power Tools in Modern Industries: Navigating Safety Standards

- Example Publisher – Safeguarding Against Hazards: The Importance of Occupational Safety Standards in Power Tool Use

- Example Publisher – Emphasizing Collective Responsibility in Safety Standards

- Example Publisher – Mastering Power Tool Safety: Protecting Property and Enhancing DIY Success

- Example Publisher – Safeguarding Your Power Tools: Why Safety Practices Matter

- Example Publisher – Navigating the Legal Landscape of Safety Standards for Power Tools

- Example Publisher – Comprehensive Power Tool Safety Tips for a Secure Workspace