What are some safety rules to follow when using power tools in a science lab?

Elevating Safety Standards: The Crucial Role of Safety Practices in Power Tool Use within Science Labs

In any scientific environment, the stakes are high. Conducting experiments, developing innovative projects, and utilizing various tools ultimately hinge on one paramount principle: safety. This holds especially true when power tools enter the scene. The importance of adhering to stringent safety practices while using these tools cannot be overstated, as even minor lapses can lead to severe consequences. In this article, we delve into the various facets of ensuring safety in a science lab where power tools are part of the daily landscape.

Understanding the Risks Associated with Power Tools

Power tools, such as drills, saws, and sanders, are indispensable in enhancing efficiency and precision in tasks ranging from data collection to building prototypes. However, their power also presents unique risks. Common hazards include:

- Cuts and Lacerations: Power tools can easily cause severe injuries if not handled correctly or if safety guards are removed.

- Electric Shock: Improper use of electric tools can lead to electric shocks, especially in environments where liquids are present.

- Repetitive Strain Injuries: Prolonged use of power tools can lead to repetitive strain injuries, such as carpal tunnel syndrome.

- Noise-Induced Hearing Loss: Many power tools, particularly drills and saws, produce high noise levels that can damage hearing over time.

With awareness of these risks, it becomes evident why establishing strict safety protocols is essential in any lab setting that incorporates power tools. Source

Key Safety Practices for Power Tool Use in Science Labs

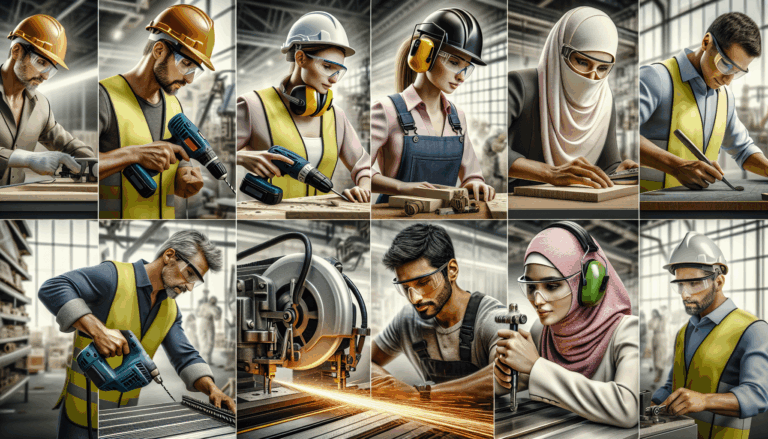

1. Personal Protective Equipment (PPE)

Before commencing any task with power tools, individuals should always wear appropriate personal protective equipment. This includes:

- Safety Goggles: Essential for eye protection against flying debris.

- Ear Protection: Useful in reducing noise exposure that can lead to hearing loss.

- Gloves: While they provide hand protection, it’s crucial to choose the right type of gloves that do not compromise grip.

- Dust Masks: Protect against inhaling harmful dust and particles generated during tool use.

Implementing these PPE requirements is crucial for maintaining a safe working environment. Source

2. Training and Familiarization

All personnel should undergo comprehensive training on tool operation and safety protocols. Key training elements include:

- Tool Operation: Understanding how to correctly operate each power tool helps in mitigating risks.

- Emergency Procedures: Familiarizing everyone with emergency procedures ensures quick and effective responses in case of an accident.

- Tool-Specific Safety Guides: Each power tool may have specific safety guidelines; knowing these can prevent misuses.

Training is a foundational element in fostering a skilled and safety-conscious user. Source

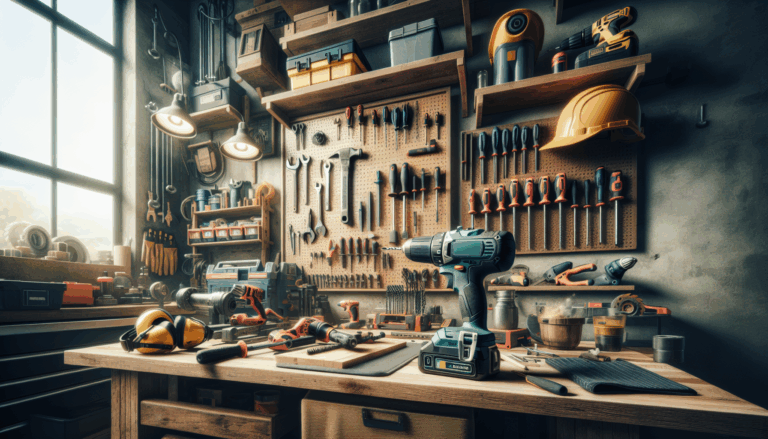

3. Workspace Organization

Maintaining a tidy workspace is integral to safety. Consider these organizational tips:

- Clear Working Area: Ensure that the area around the power tools is free of clutter to avoid tripping hazards.

- Storage Solutions: Store tools properly when not in use, ideally in designated places to promote easy access.

- Proper Lighting: Adequate lighting allows clear visibility, reducing the chance of accidental injuries.

A well-organized workspace not only improves safety but also enhances productivity. Source

4. Regular Tool Maintenance

Regular inspection and maintenance of power tools are crucial for safe use. Consider the following practices:

- Routine Checks: Inspect tools for any damage, wear, or malfunctions before use.

- Cleaning: Regularly clean tools after use to ensure they remain in good working condition and reduce the risks of accidents.

- Repairs by Professionals: If a tool malfunctions, it should be repaired by qualified personnel to avoid hazards.

Routine maintenance ensures tools operate effectively and safely throughout their lifespan. Source

5. Safe Operating Procedures

Establishing and adhering to safe operating procedures can significantly reduce accidents. Important practices include:

- Two-Handed Operation: Whenever possible, use both hands to operate power tools, ensuring better control.

- Avoid Distractions: Stay focused on the task at hand and avoid distractions that can lead to accidents.

- Stop and Analyze: If a job seems unclear or risky, take a moment to reassess the task and determine the safest approach before proceeding.

Engaging in safe practices empowers lab personnel to act with confidence and safety. Source

Emergency Preparedness

Despite all precautions, accidents can still happen. Hence, it is crucial to be prepared for emergencies:

- First Aid Kits: Ensure that fully stocked first aid kits are accessible in the lab.

- First Aid Training: Training staff in first aid can make a critical difference in an emergency.

- Emergency Contacts: Maintain a list of emergency contacts and procedures visibly posted in the lab.

Being prepared for emergencies reduces panic and can save lives in critical situations. Source

Cultivating a Safety Culture

Establishing a culture of safety within a science lab requires commitment from everyone. Here are some strategies to foster such a culture:

- Safety Meetings: Organize regular safety meetings to discuss potential hazards and safety improvements.

- Encouraging Reporting: Create an environment where reporting hazards or unsafe practices is welcomed and acted upon swiftly.

- Rewarding Safe Practices: Recognize individuals or teams who exemplify proper safety measures, reinforcing the importance of following protocols.

A strong safety culture encourages everyone to take personal responsibility for maintaining safe practices. Source

Conclusion

Integrating power tools into scientific endeavors can enhance productivity and innovation. However, the importance of maintaining a safety-first mindset cannot be left to chance. By implementing stringent safety protocols, providing adequate training, and fostering a culture dedicated to safety, scientists and students can confidently pursue their work while minimizing risks. The responsibility for maintaining safety in the lab rests upon each individual. By being proactive and well-informed about potential dangers, everyone can contribute to a safer, healthier working environment. Remember—safety is not just a set of rules; it’s a commitment to protecting ourselves, our colleagues, and the integrity of our scientific work.