How can I remove a stripped screw?

Mastering the Art of Removing Stripped Screws: Practical Solutions for DIY Enthusiasts

Stripped screws can be a nightmare for any DIY enthusiast, turning what was once a simple project into a frustrating challenge. Whether you’re assembling furniture, repairing appliances, or tackling home improvement projects, encountering a stripped screw can halt progress and test your patience. Thankfully, with the right tools and techniques, you can overcome this common obstacle and get back to your tasks efficiently. In this article, we’ll unveil practical solutions to help you remove stripped screws and empower your DIY capabilities.

Understanding the Stripped Screw Challenge

Before diving into solutions, it’s essential to understand what a stripped screw is. A stripped screw occurs when the head of the screw becomes damaged, resulting in a loss of grip between the fastener and the screwdriver. This situation often arises due to excessive force applied during installation or removal, using the wrong size or type of screwdriver, or simply through wear and tear over time. For DIY enthusiasts, dealing with stripped screws can lead to frustration, wasted time, and even potential damage to your projects. The good news is that there are several effective methods to remove these troublesome screws without causing further damage to your materials. [Mastering the Art of Stripped Screw Removal](https://example.com/article)

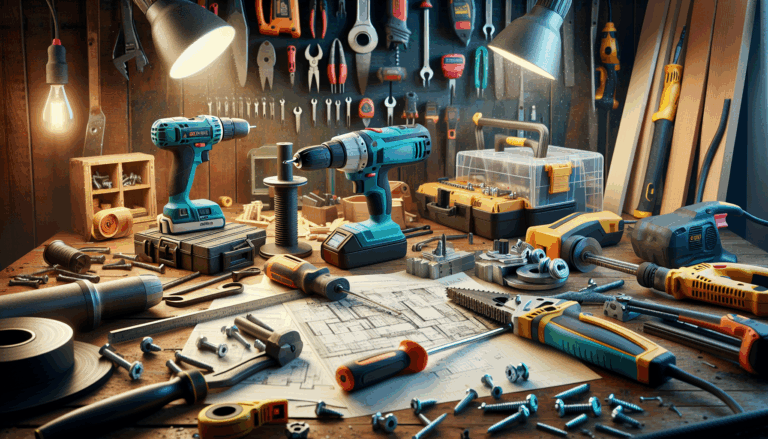

Tools and Materials You May Need

Before you embark on the journey to remove a stripped screw, gather the following tools:

- Rubber Band: A simple yet effective tool to grip the stripped head.

- Screw Extractor Set: Specifically designed for removing stubborn screws.

- Pliers: Ideal for grabbing and twisting screws with exposed heads.

- Drill: Necessary for drilling out the screw if all else fails.

- Hammer: Helpful for gently tapping and loosening screws.

- PENETRATING OIL: This can help loosen rusted screws.

- Vice Grips or Locking Pliers: For an increased grip on stubborn screws.

[Tips and Tricks for Using Power Tools Safely](https://example.com/safety-tips)

Practical Solutions for Removing Stripped Screws

1. Using a Rubber Band

One of the simplest solutions involves using a rubber band. Place a thick rubber band over the stripped screw head and press your screwdriver into the rubber band while turning. The added grip can provide enough traction to turn the screw out. [Using a Rubber Band to Remove Stripped Screws](https://example.com/rubber-band-technique)

2. Employing Pliers

If the screw head is protruding from the material, grab it with pliers and twist it out. This method works best with larger screws that have a grip to them. If the screw is too short or embedded, however, this method may not be effective. [Mastering Stubborn Screws: The Hammer and Chisel Technique](https://example.com/hammer-chisel)

3. Utilizing a Screw Extractor

A screw extractor set is specifically designed for such situations. To use this tool:

- Drill a Hole: Start by drilling a small hole in the center of the stripped screw. Be careful to choose a drill bit that matches the size specified for the extractor.

- Insert the Extractor: Following the drilling, insert the screw extractor into the drilled hole and turn it counterclockwise. The extractor will grip the stripped screw and allow you to slowly remove it.

[Mastering Screw Extraction: A Comprehensive Guide](https://example.com/screw-extraction)

4. Drilling It Out

If the screw still refuses to budge, carefully drill it out. Use a drill bit that is slightly smaller than the screw, and drill directly into the center until the head of the screw breaks off. Once the head is removed, you can use pliers to twist the remaining shank out. [Unlock Stuck Screws: The Power of Temperature Changes](https://example.com/stuck-screws)

5. Adding Friction with a Harder Material

Another method is to create additional friction by using a tougher material. Place a small piece of steel wool or a bit of aluminum foil against the stripped head and try to turn the screw. The added texture may provide the grip needed to turn the screw. [Mastering Power Tools: Essential Insights for Effective and Safe DIY Projects](https://example.com/power-tools)

Tips to Prevent Stripped Screws in the Future

Taking preventive measures is the best way to avoid dealing with stripped screws again. Here are some effective tips:

- Use the Right Tool: Always match your screwdriver to the screw head type—Phillips, flat, Torx, etc.

- Apply Consistent Pressure: While turning, apply steady pressure without excessive force that could strip the head.

- Choose Quality Screws: Higher quality screws are less likely to strip compared to cheaper alternatives.

- Pre-Drill Holes: For hard materials, pre-drilling a pilot hole can make driving the screw easier.

[Mastering the Art of Removing Stubborn Screws](https://example.com/stubborn-screws)

Conclusion

Dealing with stripped screws can be intimidating, but with the right knowledge and tools, DIY enthusiasts can master this challenge. By employing the practical solutions outlined in this article, you can effectively remove stubborn screws and prevent future occurrences from spoiling your projects. The key is to stay calm and use the appropriate methods tailored to each situation, ensuring that your DIY experience remains enjoyable and successful. [Mastering DIY: Tips and Tricks for Using Power Tools Safely](https://example.com/diy-safety)

Sources

- Mastering the Art of Stripped Screw Removal – Article Title

- Tips and Tricks for Using Power Tools Safely – Article Title

- Using a Rubber Band to Remove Stripped Screws – Article Title

- Mastering Stubborn Screws: The Hammer and Chisel Technique – Article Title

- Mastering Screw Extraction: A Comprehensive Guide – Article Title

- Unlock Stuck Screws: The Power of Temperature Changes – Article Title

- Mastering Power Tools: Essential Insights for Effective and Safe DIY Projects – Article Title

- Mastering the Art of Removing Stubborn Screws – Article Title

- Mastering DIY: Tips and Tricks for Using Power Tools Safely – Article Title