What are some fire safety tools to use when working with power tools?

Essential Fire Safety Tools for Power Tool Users: Protect Yourself and Your Workspace

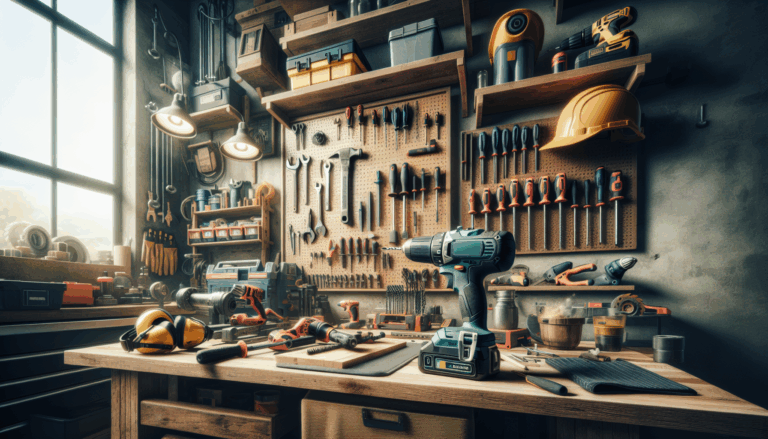

Working with power tools requires more than just skill – it demands proper safety precautions. The sparks, heat, and flammable materials involved in power tool use create significant fire hazards that every DIY enthusiast and professional should prepare for. This comprehensive guide covers the essential fire safety tools you need and best practices to keep your workspace safe.

1. Fire Extinguisher: Your First Line of Defense

A quality fire extinguisher is non-negotiable for any workspace using power tools. Look for a multipurpose extinguisher rated for:

- Class A fires: Wood, paper, cloth

- Class B fires: Flammable liquids like gasoline or paint thinner

- Class C fires: Electrical fires from tools or wiring

Mount your extinguisher in an easily accessible location and check the pressure gauge monthly. Remember the PASS technique: Pull the pin, Aim at the base, Squeeze the handle, and Sweep side to side.

2. Fire Blanket: Quick Response for Small Fires

Fire blankets are simple yet effective for smothering small fires or wrapping around someone whose clothing has caught fire. Choose a blanket made from flame-resistant fiberglass or wool. To use:

- Pull the blanket from its pouch

- Hold by the corners and gently place over flames

- Leave in place until completely cool

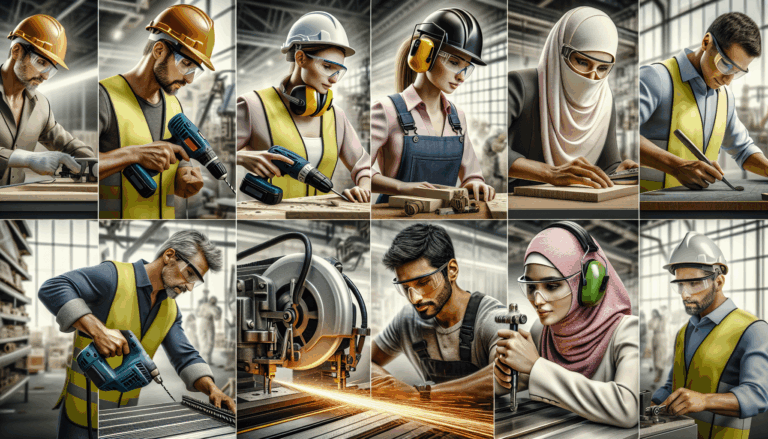

3. Heat-Resistant Gloves: Protect Your Hands

Tools like angle grinders and welding equipment generate intense heat. Quality heat-resistant gloves:

- Prevent burns from hot surfaces

- Reduce fire risks from accidental tool drops

- Should be rated for at least 500°F/260°C

Look for gloves made from Kevlar or leather that allow proper dexterity.

4. Heat-Resistant Mat: Shield Your Work Surface

These mats provide a safe, non-flammable surface for hot tools and catch sparks. Benefits include:

- Protecting work surfaces from scorch marks

- Preventing accidental ignition of flammable materials

- Ideal for soldering, grinding, and welding tasks

Choose durable silicone or fiberglass mats that can withstand high temperatures.

5. Fireproof Storage: Secure Flammable Materials

Proper storage of flammable materials is crucial. Fireproof cabinets:

- Prevent fires from spreading

- Protect volatile substances from ignition sources

- Help maintain an organized workspace

Look for UL-listed or FM-approved containers with secure latches.

6. Smoke Detector: Early Warning System

A properly installed smoke detector provides critical early warning. For workshops:

- Choose dual-sensor detectors (ionization and photoelectric)

- Install near workstations and exits

- Test monthly and replace batteries annually

Additional Fire Safety Tips

Beyond equipment, these practices enhance safety:

- Maintain ventilation: Disperse flammable fumes

- Keep workspace clean: Remove sawdust and debris

- Unplug tools when not in use: Prevent electrical fires

- Follow manufacturer guidelines: Proper tool use reduces risks

Final Thoughts

Fire safety should be an integral part of every power tool user’s routine. By investing in the right equipment and adopting safe practices, you can focus on your projects with confidence, knowing you’re prepared for potential hazards. Remember – prevention is always better than dealing with an emergency.

Sources

Footnote:

Original Title: Essential Fire Safety Tools for Power Tool Users

Author: Brent Farrell

Category: Power Tool Basics

Keywords: power tool fire safety, workshop fire prevention, heat-resistant work gear,