What are the general guidelines for operating power tools?

Read the Manual Thoroughly

Before operating any power tool, always consult the manufacturer’s manual. This essential document provides critical information about proper operation, safety precautions, and maintenance requirements. Skipping this step is like driving a car without knowing the controls – both risky and unnecessary. The manual contains model-specific details that generic safety guidelines might miss, including torque settings, blade orientations, and electrical requirements.

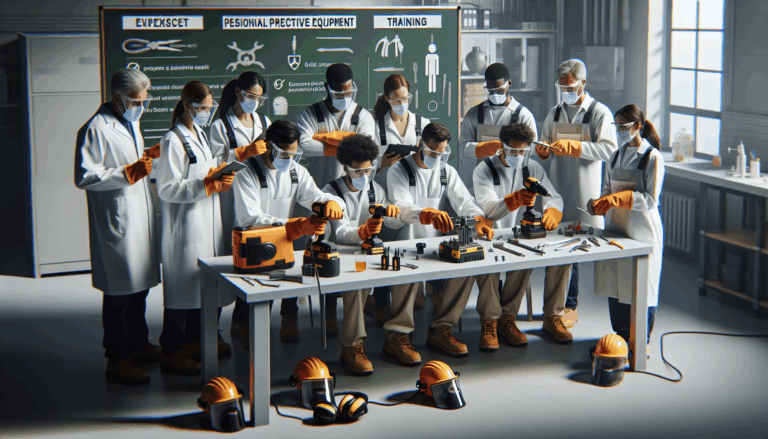

Gear Up for Safety

Proper personal protective equipment (PPE) is non-negotiable when working with power tools. Essential safety gear includes ANSI-approved safety goggles to protect against flying debris, hearing protection for tools exceeding 85 decibels, and cut-resistant gloves. For tasks generating fine particles like sanding or concrete cutting, use NIOSH-approved respirators. Remember that loose clothing or jewelry can become entanglement hazards with rotating tools.

Inspect Before Use

Conduct a thorough inspection of your power tools before each use. Check for frayed cords, loose components, and proper functioning of safety features like blade guards. Test the tool’s operation without load to ensure smooth performance. Pay special attention to cutting edges – dull blades require more force and increase kickback risk. If you notice any abnormalities, tag the tool out of service until repairs can be made.

Choose the Right Tool

Selecting the appropriate tool for each task is fundamental to both safety and quality results. For example, use a hammer drill for masonry work rather than forcing a standard drill. Consider the material, required precision, and duration of use when selecting tools. Using undersized tools for heavy-duty jobs can lead to overheating and premature failure, while oversized tools may be difficult to control precisely.

Prep Your Workspace

Create a safe working environment by ensuring adequate lighting, ventilation, and clear access to emergency shutoffs. Secure your workpiece with clamps or vises to allow two-handed tool operation. Keep floors clean and dry to prevent slips, and maintain a 3-foot clearance around your work area. Designate specific zones for tool operation versus material handling to minimize trip hazards.

Master the Technique

Develop proper tool handling techniques through practice and education. Maintain balanced footing and proper body positioning relative to the tool’s operation. Let the tool do the work – forcing materials increases accident risks. For cutting tools, understand grain direction and proper feed rates. Consider taking professional training courses for complex tools like table saws or routers to learn advanced safety techniques.

Keep a Firm Grip

Maintain secure control of power tools using both hands when designed for such operation. Use auxiliary handles on heavy tools like rotary hammers. Ensure your grip remains dry and clean – consider anti-vibration gloves for extended use. Be particularly cautious with kickback-prone tools like circular saws, keeping your body positioned to resist sudden movements while maintaining control.

Mind the Cords

For corded tools, use heavy-duty extension cords rated for the tool’s amperage to prevent overheating. Route cords away from cutting paths and high-traffic areas. When working at height, secure cords to prevent dangerous drops. Consider cord management systems like retractable reels for permanent workshop setups. Regularly inspect cords for damage and replace immediately if compromised.

Disconnect When Idle

Develop the habit of unplugging tools or removing batteries whenever they’re not in active use. This prevents accidental startups during adjustments or when changing accessories. For cordless tools, store batteries separately in climate-controlled conditions. Implement a lockout/tagout system in shared workspaces to ensure tools remain de-energized during maintenance.

Store Tools Properly

Proper storage extends tool life and maintains safety. Clean tools thoroughly before storage and apply light machine oil to metal surfaces to prevent rust. Use original cases or dedicated storage systems that protect from dust and moisture. Store batteries at 40-60% charge in temperature-controlled environments. Implement a shadow board system for quick visual inventory of your tools.