How can I maintain my woodworking tools for power tool use?

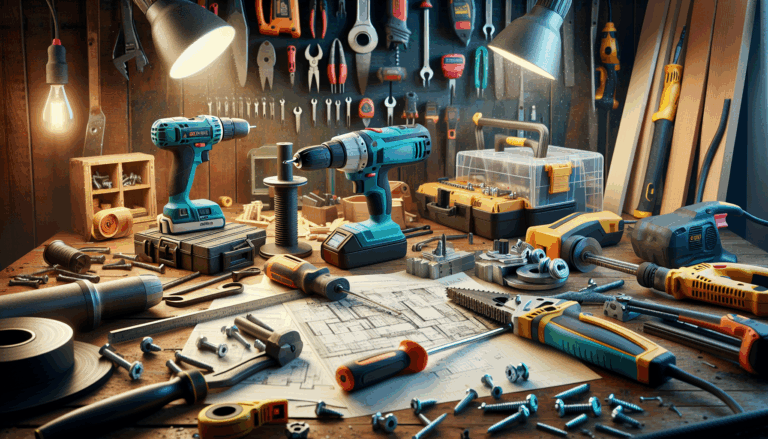

Regular Cleaning of Woodworking Tools

Regular cleaning of woodworking tools is essential not only for the longevity of the tools but also for maintaining safety and efficiency during projects. Tools like saws, drills, and chisels can accumulate dust, resin, and moisture, leading to rust and reduced functionality. It’s recommended to clean tools after each use, particularly after working with materials like wood, which can leave behind residues.

To effectively clean woodworking tools, consider the following steps:

- Remove Debris: Use a stiff brush or compressed air to dislodge any dust or debris.

- Wipe Down: Use a cloth soaked in mineral spirits or a specialized tool cleaner, ensuring all surfaces are free from grime or sap [Source: Wood Magazine].

- Protect Against Rust: After cleaning, apply a thin coat of oil to metal parts to prevent rusting; light machine oil or tool-specific oils work well [Source: Woodworkers Guild of America].

- Store Properly: Ensure tools are stored in a dry environment to minimize moisture exposure.

Neglecting regular maintenance can result in diminished cutting performance, safety risks, and ultimately higher costs due to the need for replacements. For further guidance on tool management and maintenance, check out our article on Power Tool Usage Projects.

Importance of Lubrication

Applying oil to bearings, gears, and joints is essential for maintaining the longevity and efficiency of your tools. Lubrication serves to reduce friction, resulting in minimal wear and tear on mechanical parts. Without proper lubrication, tools face increased friction that can lead to overheating and damage. For example, bearings and gears that operate without sufficient oil are prone to premature failure, causing unnecessary disruptions and replacement costs.

Research indicates that lubricants not only diminish friction but also protect against corrosion and wear by forming a protective layer on metal surfaces [Source: Machinery Lubrication]. Regularly applying oil at recommended intervals can help maintain optimal performance in power tools, ultimately extending their lifespan and efficiency.

For more information on how to safely maintain and operate power tools, check out our article on essential power tool brands.

Periodic Inspections and Tightening Screws

Periodic inspections and tightening of screws are crucial for maintaining the stability and safety of structures and machinery. Loose screws can compromise the integrity of equipment, potentially leading to accidents or failures. It is recommended to conduct these checks regularly — ideally every few months, or more frequently in high-use areas or environments prone to vibration.

When tightening screws, it’s essential to use the correct tools, such as a torque wrench or screw gun, to apply the proper amount of force without damaging the material. Many people find using a hand-held screwdriver makes it easier to feel the resistance as they tighten, which can help avoid over-tightening. Additionally, applying a thread-locking adhesive can prevent screws from loosening due to movement or vibration.

It is vital to recognize the dangers associated with neglecting screw maintenance. For instance, machinery with loose screws can lead to malfunction or even accidents, posing injury risks to operators. Reports have shown that inadequate maintenance practices directly correlate with a higher incidence of workplace injuries [Source: OSHA].

Overall, adhering to these maintenance protocols can enhance safety and prolong the life of both tools and structures. For more specific guidance on effective tightening and tools, check out our articles on power tool basics and best practices for screw maintenance.

Keeping Blades and Bits Sharp

Keeping blades and bits sharp is essential for enhancing efficiency and reducing the strain on tools during use. A sharp tool cuts more cleanly, requiring less force, which not only improves accuracy but also prolongs the tool’s life by minimizing wear and tear. For instance, using dull drill bits can lead to excessive friction and heat, increasing the likelihood of tool breakage and injury.

Regular maintenance practices, such as honing and sharpening blades and bits, contribute significantly to operational performance. Various techniques can be employed, including using sharpening stones or professional sharpening services. For power tools, this often means following manufacturer guidelines on blade or bit maintenance to achieve optimal results.

Moreover, a well-sharpened tool increases productivity by reducing cutting time and improving the quality of cuts, which is particularly vital in projects involving fine woodworking or assembly work. The inverse is also true; dull tools can negatively impact both safety and productivity, leading to errors and potential accidents on the worksite [Source: Power Tool Projects].

For those seeking more detail on proper sharpening techniques, consider exploring articles about saw and drill maintenance to ensure your power tools always perform at their best [Source: Power Tool Basics].

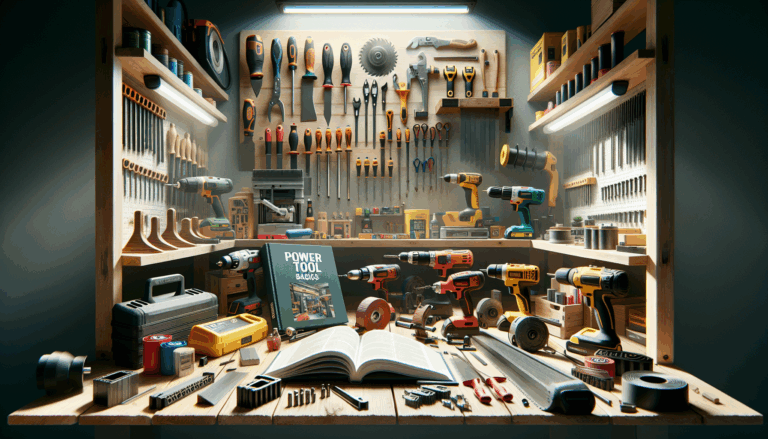

Proper Storage of Power Tools

Storing your power tools in a clean and dry environment is essential for maintaining their condition and longevity. The effects of extreme temperatures and humidity can compromise tools, leading to rust, corrosion, and malfunction. For instance, humidity not only accelerates rusting of metal components but can also damage electrical circuits and insulation, resulting in costly repairs or replacements. According to experts at Family Handyman, keeping tools in a climate-controlled area minimizes these risks significantly.

Additionally, a clean storage area prevents the accumulation of debris and dirt, which can get into mechanical parts and affect performance. It’s advisable to use materials like moisture-resistant cabinets or shelves for storing these tools. Many recommend using silica gel packets or a dehumidifier in the storage area to absorb excess moisture and further protect your tools from environmental damage Fine Woodworking.

Implementing these best practices not only extends the life of your power tools but also enhances safety during use, ensuring that you can rely on them whenever needed [Source: One Power Tool].

Ensuring Safety in Woodworking

Ensuring safety in woodworking is paramount, requiring proper safety gear and correct tool usage to prevent accidents. Essential safety gear includes goggles, gloves, dust masks, and hearing protection. Goggles protect against flying debris, while gloves provide a better grip and shield hands from cuts. Dust masks are crucial for respiratory protection, especially when sanding or cutting wood. Hearing protection is necessary when operating loud machinery such as table saws or routers.

Accidents in woodworking can often be attributed to improper use of tools. According to the U.S. Consumer Product Safety Commission (CPSC), nearly 300,000 injuries related to woodworking tools are reported annually, with many being preventable through adherence to safety protocols [Source: CPSC].

Additionally, employing ergonomic practices can reduce the risk of strain and injuries. Choosing the right tools for the job, maintaining a clean workspace, and following manufacturer’s instructions can further enhance safety. It’s important to familiarize oneself with the specific functions and risks associated with each tool, such as understanding kickback in saws and ensuring workpieces are properly secured while cutting [Source: One Power Tool].

For more detailed tips on using power tools safely, you can refer to our article on safety tips for using power tools.

Inspection of Power Tool Cords and Plugs

Regular inspection of power tool cords and plugs is vital for maintaining safety and preventing electrical hazards. Users should routinely check for signs of damage such as frays, cuts, or exposed wires, as these can lead to shorts or potentially severe electrical shocks. The Occupational Safety and Health Administration (OSHA) emphasizes that “Proper maintenance of electrical equipment is essential for workplace safety” [Source: OSHA].

When inspecting cords and plugs, ensure that the insulation is intact, the connectors are not loose, and there are no signs of burning or melting. If any damage is found, it’s crucial to stop using the tool immediately and either repair or replace the damaged components [Source: NCBI].

Utilizing tools equipped with Ground Fault Circuit Interrupters (GFCIs) can additionally enhance safety by providing protection against electrical shocks in wet or outdoor environments. Regularly integrating these checks into your routine maintenance can greatly reduce the risk of accidents or injuries while using power tools [Source: One Power Tool Blog].

Sources

- CPSC – CPSC Releases New Woodworking Tool Safety Guidelines

- Family Handyman – How to Store Tools in a Shed or Garage

- Fine Woodworking – Tool Storage 101

- Machinery Lubrication – Lubrication Reduces Wear and Friction

- NCBI – Safety and health implications of overhead electrical power tool cords

- OSHA – Occupational Safety and Health Administration

- Wood Magazine – Cleaning Woodworking Tools

- Woodworkers Guild of America – Top 5 DIY Tools Care Tipswoodworking tools