How can I safely remove a stripped screw without damaging the material?

Understanding Stripped Screws

Stripped screws can be a frustrating issue, often resulting from various causes and presenting multiple challenges when it comes to removal. The primary reasons screws become stripped include using the wrong size or type of screwdriver, applying excessive force, or over-tightening the screws. Additionally, using worn-out or damaged tools can exacerbate the problem, leading to a poor fit and eventual stripping of the screw head [Source: YnetNews].

Once a screw is stripped, removing it can be tricky. The stripped head can prevent traditional methods, such as turning the screw with a screwdriver, from working effectively. This problem multiplies when multiple screws are stripped simultaneously [Source: Forbes]. Common removal methods include using rubber bands to create friction, employing screw extractors, or drilling out the screw; each method has its challenges and may require precision.

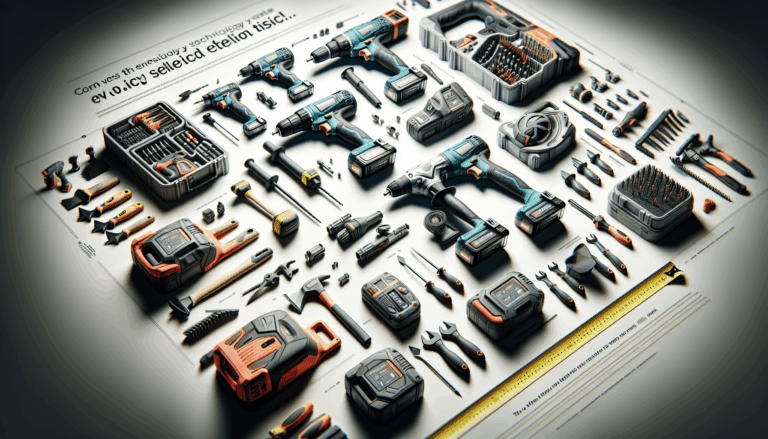

Power Tools for Stripped Screws

When tackling stripped screws, having the right tools can make all the difference. Drills and impact drivers specifically designed for these scenarios offer unique features to efficiently remove stuck screws.

Impact Drivers

One of the best tools for removing stripped screws is an impact driver. These devices harness rotational force and hammering actions, enabling them to loosen stubborn screws without damaging the surrounding material. The DEWALT DCF887B 20V MAX XR is highly recommended for its power and compact design [Source: One Power Tool]. Similarly, the Makita XDT131 18V LXT is praised for its precision torque control, making it a solid choice for DIY enthusiasts and professionals alike.

Cordless Drills

For those who prefer corded tools, the BLACK+DECKER LDX120C 20V MAX is versatile and lightweight, helping manage stripped screws effectively. Bosch’s GSR12V-140B22 12V is well-regarded for its durability and battery life, providing strong support for challenging removal tasks.

Ergonomic Electric Screwdrivers

Electric screwdrivers can also play a vital role in this process. The WORX WX252L 20V SD is designed for easy handling, making it a favorite for removing screws without stripped heads. It comes equipped with a built-in LED light and battery gauge for convenience in tight spaces.

Safety First

When using power tools for screw extraction, safety measures are paramount to prevent injuries and ensure efficiency. Here’s a comprehensive overview of the key precautions and best practices:

- Wear Personal Protective Equipment (PPE): Always use appropriate PPE such as safety goggles, gloves, and hearing protection to minimize risks [Source: Ynet News].

- Inspect Your Tools: Before use, check your power tools for wear or damage. Address any issues immediately [Source: Forbes].

- Use the Right Tool for the Job: Ensure you’re using the correct type of power tool for screw extraction to reduce the risk of damage [Source: The Register].

- Stabilize Your Workpiece: Secure the material you’re working on to prevent movement while drilling [Source: Ynet News].

- Maintain a Safe Workspace: Keep your work area clean and well-lit to avoid trip hazards [Source: Forbes].

- Follow Operating Instructions: Always read the manufacturer’s manual for safety guidelines [Source: The Register].

- Avoid Distractions: Focus on the task at hand to prevent accidents [Source: Ynet News].

- Unplug When Changing Bits: Unplug power tools before making adjustments to prevent accidental startups [Source: Forbes].

Using a Drill to Remove Stripped Screws

Removing stripped screws can be daunting, but with the right drill techniques, it can be accomplished effectively. Follow these steps:

- Gather Materials: Collect a drill, screw extractor set, left-handed drill bit, and lubricant.

- Assess the Screw: Determine if the screw head is stripped; if it is partially intact, you may be able to use a larger bit or a flathead screwdriver.

- Lubricate: Apply penetrating oil around the screw and let it sit for several minutes.

- Drill a Pilot Hole: Use a left-handed drill bit to create a new pilot hole in the screw [Source: One Power Tool].

- Install a Screw Extractor: Insert the extractor into the pilot hole and turn counter-clockwise.

- Clear the Hole: Clean out any debris from the hole after removing the screw.

- Replace the Screw: Choose a new screw that fits tightly.

Using an Impact Driver to Remove Stripped Screws

To effectively utilize an impact driver for removing larger stripped screws, consider these techniques:

- Select the Right Bit: Use a high-quality bit matching the stripped screw.

- Use Additional Friction: Apply penetrating oil around the screw before applying torque.

- Adjust Impact Driver Settings: Start with a lower torque setting and gradually increase it.

- Rocking Motion: Use a gentle rocking motion to engage the screw at multiple angles.

- Drilling Out the Screw: If basic methods fail, consider using a drill bit slightly smaller than the screw diameter to effectively drill it out.

After Removing the Stripped Screw

Once you successfully remove a stripped screw, ensure you clean the hole to remove debris that could impede the installation of a new screw. Often, you can reuse the hole, but if it appears damaged, consider using a larger screw or a wooden dowel for a secure anchor point [Source: Ynet News].

Stripped Screw Removal FAQ

Understanding effective methods can simplify the task of removing stripped screws. Here are some common questions:

- What causes screws to get stripped? Stripped screws often result from mismatched tools, excessive force, or worn-out screwdrivers.

- What tools help remove stripped screws? Tools like screw extractors, rubber bands, and drills can assist in the removal process.

- Can screws be reused? Yes, often, you can reuse the hole unless it’s damaged, in which case larger screws may be used.

Product Recommendations

Effective tools can simplify the process of removing stripped screws, ensuring you can complete your projects efficiently. Recommended tools include screw extractors from Irwin, high-quality rubber bands, left-handed drill bits, and robust impact drivers from reputable brands [Source: One Power Tool].

Conclusion

Employing either an impact driver, a cordless drill, or an ergonomically designed electric screwdriver can significantly enhance your efficiency in removing stripped screws, enabling you to complete projects smoothly. By following safety measures and using the right techniques, you can avoid pitfalls and frustrations in your DIY endeavors.