How important is safety when using power tools?

Importance of Power Tool Safety

Operating power tools without proper safety measures can lead to significant injuries and tragic accidents. Statistics reveal that over 400,000 people in the U.S. visit emergency rooms annually due to power tool-related injuries, with lacerations and fractures being among the most common types of injuries incurred [CDC]. The risks associated with power tool operation include kickback, electrical hazards, and projectiles from cutting tools that can cause serious harm if proper precautions are not followed.

Wearing personal protective equipment (PPE) is crucial when using power tools. Quality safety glasses can prevent eye injuries, while gloves can protect against cuts and abrasions. According to the Occupational Safety and Health Administration (OSHA), using the appropriate PPE can significantly reduce the severity of injuries in case of an accident.

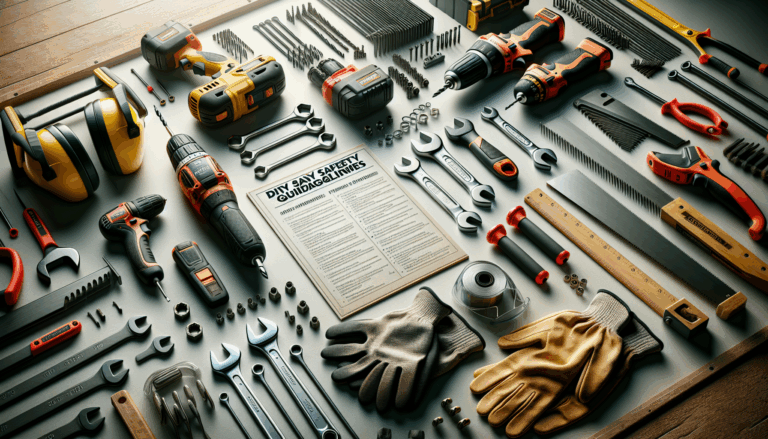

To mitigate risks, users should adhere to several safety guidelines. These include:

- Read the owner’s manual: Understand your tool and follow the manufacturer’s operating instructions.

- Inspect tools before use: Ensure power cords are intact, blades are sharp, and safety features are functioning properly.

- Set up a safe work area: Keep the workspace clear of obstacles and ensure proper ventilation when using power tools indoors.

- Use the right tool for the job: Each tool is designed for specific tasks; using them incorrectly can increase the likelihood of accidents.

- Stay focused: Avoid distractions while working and never operate tools under the influence of drugs or alcohol.

Neglecting these safety measures can lead to severe consequences, not only for the individual operating the power tools but also for bystanders. An accident can result in long-term injuries, financial burdens due to medical costs, and even legal implications if safety standards are not met.

For additional safety practices and insights, refer to our article on Power Tool Usage and Projects.

Frequent Causes of Power Tool Accidents and Prevention Strategies

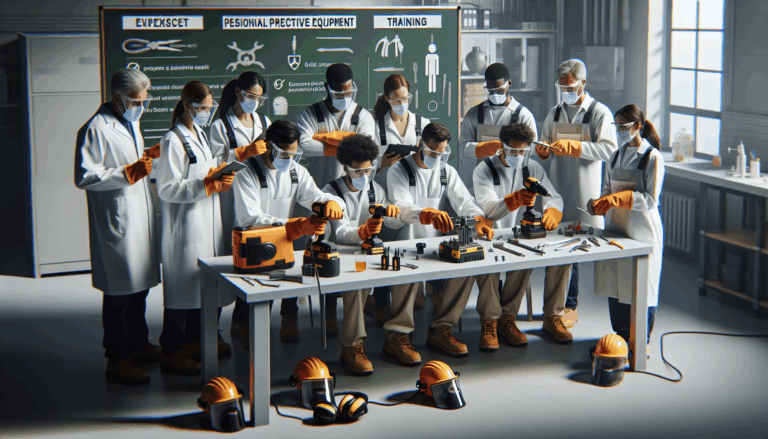

Power tool accidents can arise from various sources, with improper use being a major contributor. According to the U.S. Occupational Safety and Health Administration (OSHA), common causes include inadequate training, distractions, and equipment failure. In fact, nearly 30% of power tool injuries are due to misuse and lack of protective gear.

To prevent these incidents, consider the following practical strategies:

- Training and Education: Ensure that all users are properly trained in the safe operation of power tools. This training should cover specific tools being used, highlighting potential hazards and safe working practices [OSHA].

- Safety Gear: Always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and ear protection to minimize injuries [CDC].

- Regular Maintenance: Keep power tools in good working condition through regular maintenance checks. Faulty equipment should be repaired or replaced immediately [Safety + Health Magazine].

- Work Environment: Maintain a clutter-free and well-lit workspace to reduce the risk of accidents. Ensure that the area is safe, with no slip or trip hazards present [National Safety Council].

- Distraction Management: Avoid distractions when using power tools. This includes focusing solely on the task at hand without multitasking or using mobile devices [Safe Workers].

By implementing these strategies, users can significantly reduce the likelihood of power tool accidents, fostering a safer working environment overall. For more information on ensuring safety in all tool usage, explore our comprehensive guide on effective power tool projects here.

Key Guidelines for Using Power Tools Safely

To ensure safety while using power tools, follow these key guidelines:

- Read the Manual: Always start by reading the user manual that comes with your power tool. This ensures you understand the specific operating procedures and safety precautions needed for that tool.

- Wear Protective Gear: Personal protective equipment (PPE) is crucial. Always wear safety goggles, gloves, and ear protection to guard against potential hazards.

- Keep Work Area Clean: A cluttered workspace increases the risk of accidents. Ensure that your work area is organized and free of unnecessary items to minimize distractions.

- Inspect Tools Regularly: Before use, inspect power tools for any damage or wear. Check cords, blades, and other components to ensure they are functioning correctly.

- Use Proper Technique: Maintain the proper grip and stance while operating tools. Use both hands where applicable, and ensure you are standing in a stable position to avoid falls.

- Stay Focused: Avoid distractions while operating power tools. Never use them under the influence of alcohol or drugs, and keep your mind focused solely on the task at hand.

- Disconnect Power: Always turn off and unplug power tools when not in use. This will prevent accidental activation, which can lead to injuries.

- Use Tools for Their Intended Purpose: Follow the manufacturer’s guidelines regarding the appropriate uses for each power tool. Using them outside their intended purposes can lead to malfunction and personal injury.

- Be Mindful of Surroundings: Make sure your workspace is free from hazards like loose wires or wet floors. Keep bystanders away from your work area to avoid accidents.

- Seek Help if Uncertain: If unsure about how to use a specific power tool safely, ask for help or consult a professional to prevent accidents.

By adhering to these guidelines, you can significantly reduce the risk of injuries while using power tools. For more information on safe tool usage, you might find our additional articles on power tool usage projects helpful.

The Importance of Regular Maintenance of Power Tools

Regular maintenance of power tools is essential not only for safety but also for prolonging their lifespan. Neglecting maintenance can lead to malfunction, which poses safety hazards for users, including the risk of injuries. A study indicated that proper tool maintenance significantly reduces accidents by ensuring that tools function correctly and safely [Forbes].

Regularly cleaning, inspecting, and replacing worn-out parts are crucial steps. For example, dull blades can strain the motor and lead to overheating, while debris buildup can obstruct ventilation and reduce efficiency. By conducting routine checks and keeping tools clean, you enhance performance and ensure they operate at their best, thus extending their useful life [The Register].

Additionally, tools that are well-maintained show improved accuracy and precision, which is especially important for demanding projects. This reduces the amount of manual correction needed and empowers users to achieve professional results consistently [Futurism]. Therefore, investing in regular maintenance is not just a good practice but a necessary one that can save money in the long run by avoiding costly repairs and replacements.

Essential Personal Protective Equipment (PPE) for Power Tool Use

Personal protective equipment (PPE) is essential for ensuring safety when operating power tools, as it significantly mitigates the risk of injuries. Common types of PPE include safety goggles, hearing protection, gloves, and sturdy footwear. These items protect against common hazards associated with power tools, such as flying debris, noise levels, cuts, and falls. For instance, according to the U.S. Bureau of Labor Statistics, over 30% of injuries related to power tools involve lacerations, which can often be prevented by wearing appropriate gloves and protective gear [BLS].

To ensure optimal protection, follow these best practices for PPE usage:

- Conduct a Risk Assessment: Before beginning work, identify potential hazards and select PPE accordingly.

- Select the Right Equipment: Use PPE specifically designed for the task at hand; for example, use anti-fog safety goggles in environments where visibility may be a concern.

- Inspect Gear Before Use: Regularly inspect PPE for wear and damage to ensure it functions perfectly.

- Ensure Proper Fit: Ill-fitting PPE may not provide adequate protection; ensure all gear fits securely and comfortably.

- Follow OSHA Guidelines: Adhere to the Occupational Safety and Health Administration (OSHA) regulations which mandate proper PPE usage to minimize workplace risks [OSHA].

Utilizing PPE not only complies with legal requirements but also fosters a culture of safety, enhancing overall productivity in environments where power tools are frequently used. For more detailed insights and personal stories related to power tool safety, consider visiting this article from our blog.

Sources

- Bureau of Labor Statistics – Occupational Injuries

- CDC – Power Tools

- Occupational Safety and Health Administration – OSHA

- CDC – Safety with Power Tools

- National Safety Council – Power Tools

- Forbes – The Importance of Maintenance

- The Register – Regular Maintenance

- Futurism – Importance of Accuracy

- Safety + Health Magazine – Tips for Safety

- Safe Workers – Top Safety Tips