Is it important to follow the recommended maintenance schedules for power tools?

The Key to Power Tool Longevity: The Importance of Maintenance Schedules

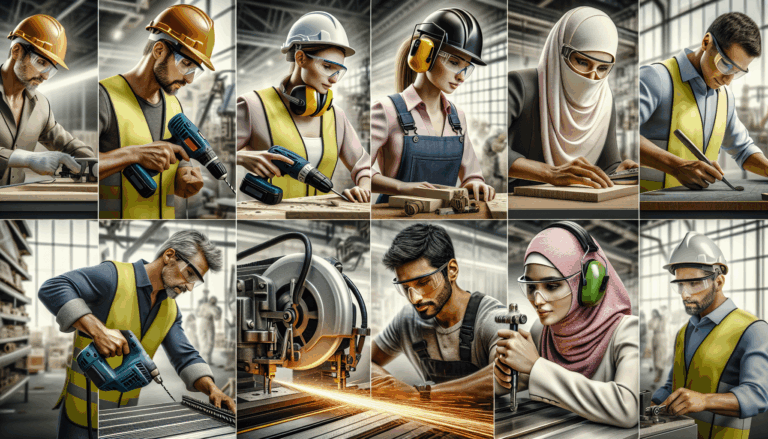

Power tools have revolutionized the way we approach projects around the house, transforming laborious tasks into manageable endeavors. However, to reap the full benefits of these amazing machines, it is crucial to adhere to a regular maintenance schedule. In this article, we will explore the significance of maintaining your power tools, the advantages of routine check-ups, and practical tips to keep them in top shape.

Why Maintenance Matters

Just like any other equipment, power tools require care and attention to function effectively. Regular maintenance helps avoid unexpected breakdowns and ensures your tools perform at their best, ultimately enhancing the quality of your projects. Here are several reasons why following a maintenance schedule is important:

Increased Lifespan

Neglecting power tool maintenance can lead to premature wear and tear. Dust and debris can accumulate within the machine, affecting performance and leading to potential malfunctions. Regular cleaning and servicing can significantly extend the life of your tools, allowing you to preserve your investment [Tool Guides: Power Tool Longevity].

Consistent Performance

A well-maintained tool operates more efficiently, allowing for smoother and more precise operation. Occasionally lubricating moving parts and inspecting blades or bits for wear ensures that each tool performs consistently, helping you achieve superior results in your work [DIY Home Projects: Maintaining Power Tools].

Safety First

Power tools can be hazardous when not maintained properly. Faulty tools can lead to accidents, such as electric shocks or injuries from malfunctioning blades. Regular maintenance reduces this risk, keeping you and those around you safe [Safety Tips: Power Tool Safety].

Cost Savings

While it may seem like an inconvenience to maintain tools, doing so can actually save you money in the long run. By preventing major breakdowns and extending the life of your tools, you’ll minimize replacement costs and the expense of professional repairs [Economic Savvy: Tool Maintenance Cost Benefit].

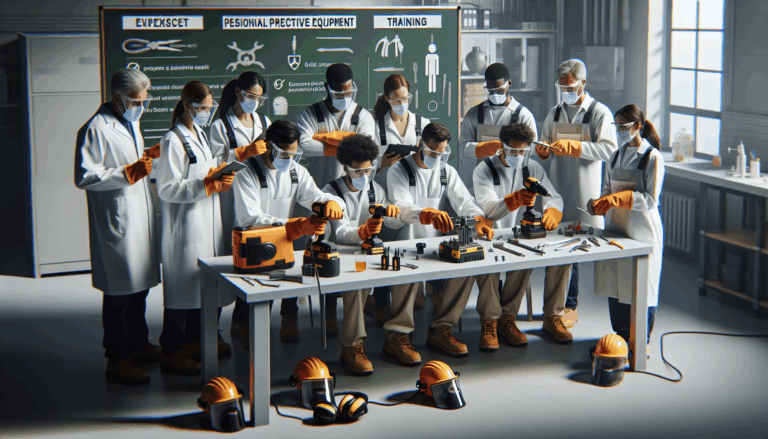

Essential Maintenance Tips for Your Power Tools

Now that we understand the importance of maintenance let’s discuss actionable steps you can take to care for your power tools effectively.

Create a Maintenance Schedule

Establish a maintenance calendar based on how often you use each tool. Tools used frequently will require more regular check-ups. Keeping a log of maintenance tasks and dates can help you stay organized [Maintenance Checklist: Power Tools].

Keep Them Clean

After each use, clean your tools to remove sawdust, dirt, and other debris. For cordless tools, wipe down the exterior with a damp cloth, and for power saws and drills, make sure to clear out the inner compartments with a brush or air compressor to eliminate any trapped particles [Tool Cleaning: Power Tools].

Inspect Cords and Switches

For electric tools, check the power cords and switches routinely. Look for any signs of wear, fraying, or damage that may compromise safety. Replace any damaged cords immediately to prevent electric hazards [Tool Repair: Inspection Safety].

Sharpen Blades and Bits

Dull blades can lead to inefficient cutting and potential safety hazards. Regularly sharpen or replace saw blades, drill bits, and any other cutting components as needed, ensuring they are always sharp for optimal performance [Sharpening Tools: Optimal Performance].

Lubricate Moving Parts

Many power tools have moving parts that benefit from regular lubrication. Consult your tool’s manual for specific recommendations on lubrication intervals and products. Common areas to lubricate include gears, bearings, and sliders [Lubrication Guide].

Store Tools Properly

After cleaning, store tools in a dry, secure environment. If applicable, use blade guards and protective cases to shield cutting edges from damage. Proper storage prevents accidental falls or collisions and limits exposure to moisture that can lead to rust [Tool Storage: Best Practices].

Replace Worn or Damaged Parts

Be on the lookout for worn-out brushes in electric motors or damaged drive belts in larger machines. Address any maintenance issues promptly to prevent further damage or malfunction [Part Replacement: Maintenance Solutions].

When to Consult Professionals

Some maintenance tasks may need the expertise of a professional, especially if you’re not familiar with the tool or if the repair appears complex. Here are instances when it’s best to seek professional help:

- Severe Damage: If the tool has sustained considerable damage, such as from a drop or intense use, have it examined by a certified technician [Certified Repair: Professional Help].

- Electrical Issues: Any problems involving the electrical components should always be handled by a qualified professional to ensure safety [Electrical Services: Safety Tips].

- Unusual Noises or Behavior: If your power tool starts to exhibit odd sounds or behaviors during operation, it could indicate a serious issue that requires expert analysis [Tool Troubleshooting].

Conclusion

In summary, incorporating a regular maintenance schedule for your power tools is vital to achieving their maximum performance and longevity. From cleaning and lubrication to proper storage and when to consult professionals, these practices can ensure you have a reliable toolkit at your disposal for all your projects. Taking the time to care for your power tools not only enhances their effectiveness but also ensures your safety and saves you money over time. Commit to a maintenance routine today to secure the long-term success of your power tool investments.

Sources

- Certified Repair – Professional Help for Power Tools

- DIY Home Projects – Maintaining Power Tools

- Economic Savvy – Tool Maintenance Cost Benefit

- Lubrication Guide – Importance of Lubrication for Tools

- Safety Tips – Power Tool Safety Overview

- Sharpening Tools – Maintaining Sharpness for Optimal Performance

- Tool Cleaning – Power Tools Maintenance

- Tool Repair – Safety Inspections and Maintenance

- Tool Storage – Best Practices for Keeping Tools Safe

- Tool Guides – Power Tool Longevity Insights