Is there a difference in quality between different brands of power tools?

Power Tool Brand Comparison

When discussing popular power tool brands, several names consistently stand out due to their reputation for quality, durability, and performance. DeWalt is renowned for its robust construction and reliable performance. Their tools often come with a three-year warranty and are known for their durability, making them a favorite among professionals and DIY enthusiasts alike. Their extensive range of cordless tools showcases innovation and user-friendly features, ideally suited for demanding environments [Source: ToolGuyd].

Milwaukee tools are celebrated for their high-performance standards and extensive line of products tailored for heavy-duty applications. Known for their innovative battery technology, Milwaukee’s tools provide excellent power and runtime, which is crucial for professionals. Their durability is evidenced by positive feedback from users across various sectors [Source: Pro Tool Reviews].

Makita combines quality with advanced technology, making their tools a top choice for many contractors. Their focus on ergonomic designs and lightweight materials enhances usability without compromising durability. The company is known for its commitment to maintaining high standards in its manufacturing processes [Source: Consumer Reports].

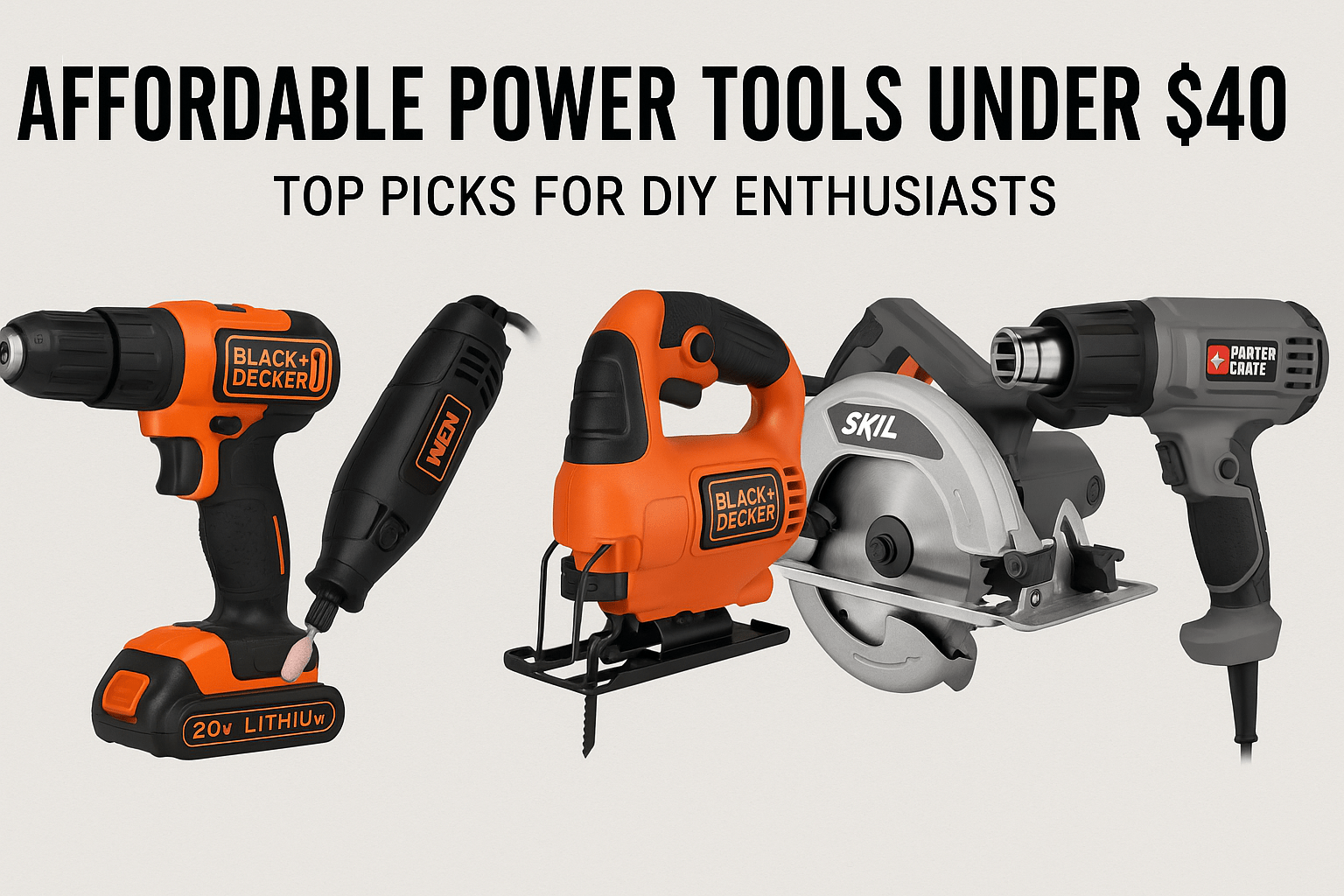

Ryobi is known for offering a wide range of affordable tools without sacrificing quality. It is particularly favored among homeowners and DIYers for its value proposition and comprehensive line of cordless tools. While they might not withstand heavy professional use, they are reliable for everyday projects [Source: Toolbox Buzz].

Bosch’s tools stand out for their precision engineering and cutting-edge technology. The brand is respected for both its power tools and accessories, with a strong reputation for reliability and durability, making them suitable for both professional settings and home use [Source: Bosch Tools].

These brands have established themselves as leaders in the power tool market, offering options that range from budget-friendly models to high-end tools for professionals. Their reputations are grounded in user feedback and performance across various applications, ensuring they remain top choices for consumers. For further insights on selecting the right tools for home improvement, check out our article on essential power tool brands for homeowners [here].

Factors Affecting Power Tool Quality

The quality of power tools is influenced by several key elements, including brand reputation, manufacturing standards, design, and materials used. A strong brand reputation often reflects a commitment to quality and customer satisfaction, making it a crucial factor for consumers. Brands like DeWalt and Makita are renowned for their reliability and performance, often resulting from decades of expertise in tool manufacturing.

Manufacturing standards play a vital role in ensuring the durability and safety of power tools. Adherence to recognized standards, such as ISO 9001, guarantees that products are made with consistent quality controls and testing procedures [Source: ISO]. This significantly reduces the risk of defects and enhances user safety.

The design of power tools, from ergonomics to power delivery systems, directly impacts their usability and effectiveness. For instance, tools that are well-balanced and designed for ease of use can reduce fatigue during extended periods of operation [Source: One Power Tool]. Additionally, the choice of materials—such as high-carbon steel for blades—can affect performance and longevity.

In summary, understanding these interrelated components can help consumers make informed choices about power tools, ensuring they invest in reliable equipment for their projects [Source: One Power Tool].

Assessing Material Quality and Construction

Power tools are critical in numerous industries and their effectiveness largely depends on the materials used and the construction methods employed. High-quality power tools often utilize robust materials such as steel, aluminum, and durable plastics which contribute to their longevity and performance. For instance, steel components provide superior strength and resistance to wear, while high-grade plastics make tools lighter and more ergonomic without compromising durability.

Additionally, advanced manufacturing techniques, such as precision machining and robust assembly processes, directly influence the quality of power tools. These methods ensure tighter tolerances and improve overall performance stability. A well-constructed power tool, utilizing high-quality materials and efficient manufacturing processes, typically exhibits reduced failure rates and extended operational life.

Innovations in materials, such as the use of composite materials and advanced coatings, further enhance durability. These innovations improve corrosion resistance and increase wear protection, which are vital for tools exposed to harsh environments. Furthermore, adhering to strict industry standards during the manufacturing process ensures that the tools maintain consistent quality and safety characteristics over time.

To explore further, you might want to check out articles like “What are the features of a good electric hand drill?” or “Power tool batteries” for insights on essential features that impact tool efficiency and longevity.

Importance of Design and Engineering in Power Tools

The design and engineering of power tools play a crucial role in their functionality, usability, and overall performance. Key factors influencing these aspects include the choice of materials, ergonomics, and the integration of innovative features.

High-quality materials such as robust plastics and durable metals enhance a tool’s lifespan and reliability. For instance, power tools designed with lightweight yet sturdy materials improve maneuverability while maintaining strength. Advanced engineering processes, including precision manufacturing, can significantly impact the tool’s accuracy and efficiency.

Ergonomics is equally vital in power tool design. Tools designed with user comfort in mind reduce strain, allowing for prolonged use without fatigue. Features like soft-grip handles, balanced weight distribution, and adjustable settings cater to a range of user preferences, thereby enhancing usability across different tasks. Research shows that ergonomic designs can lead to improved performance by increasing user confidence and reducing the risk of injury during operation.

Innovative design features such as variable speed settings, battery indicators, and quick-release mechanisms enhance performance and improve the overall user experience. These functionalities allow users to adapt tools to specific tasks easily, making them more versatile for various applications—from DIY projects to professional use.

For more insights on effective power tool usage, you can explore related articles on our site, such as safely removing a stripped screw and essential features of a good electric hand drill.

Maintenance Tips for Prolonging Power Tool Life

To ensure your power tools have an extended lifespan and optimal performance, consider the following maintenance and care practices:

- Regular Cleaning: After each use, clean the exterior of your tools using a cloth to remove dust, debris, and grime. For more thorough cleaning, use compressed air to blow out any accumulated particles from vents and crevices.

- Inspection and Prevention: Frequently check for signs of wear and tear, including frayed cords, loose parts, or rust. Addressing these issues early can prevent more significant problems down the line.

- Lubrication: Regularly lubricate moving parts such as gears, bearings, and pivot points. Use manufacturer-recommended lubricants to ensure compatibility and effectiveness.

- Battery Maintenance: For cordless tools, maintain batteries by not letting them completely drain before recharging. Store batteries in a cool, dry place and avoid extreme temperatures that can reduce battery life [Source: One Power Tool].

- Proper Storage: Store tools in a dry place, preferably in a toolbox or mounted on a designated wall rack to prevent damage. Ensure they are away from moisture to avoid rusting.

- Following Manufacturer Guidelines: Each power tool comes with specific maintenance guidelines. Always refer to the user manual for practices tailored to your tools.

- Using the Right Accessories: Ensure that all accessories and attachments are compatible with your tool. Using the incorrect accessories can lead to excessive wear.

- Scheduled Servicing: For more complex tools, consider scheduling regular servicing with a professional to ensure that everything is functioning optimally.

By adhering to these practices, you can extend the lifespan of your power tools and enhance their performance, making your projects more efficient and enjoyable. For further insights on specific tool care, check our guide on the features of a good electric hand drill [Source: One Power Tool] or explore safety tips for using power tools [Source: One Power Tool].

Conclusion: Choosing the Right Brand for Your Needs

When selecting a power tool brand, several key considerations can guide your choice for quality and performance:

- Quality & Durability: Opt for brands known for high-quality materials and construction. Tools that are built to last can withstand frequent use and endure various project demands.

- Performance: Assess the power and efficiency of the tools. Read reviews and specifications to understand how well the tools perform under heavy-duty conditions.

- Warranty & Customer Support: A solid warranty indicates a manufacturer’s confidence in their product. Brands that offer robust customer support will save you time and frustration in the long run.

- User Reviews: Feedback from other consumers can provide real-world insights into a brand’s reliability and performance.

- Brand Reputation: Consider the brand’s history and reputation in the industry. This can also relate to the availability of accessories and compatibility with other tools.

- Safety Standards: Prioritize brands that actively demonstrate their commitment to safety through compliant tools.

Investing time into researching and understanding different power tool brands can lead to better purchasing decisions that enhance your projects’ outcomes. For more insights, you can explore essential practices for using power tools safely on our blog.

Sources

- Bosch Tools – Bosch Power Tools

- Consumer Reports – Makita vs. DeWalt

- ISO – ISO 9001 Quality Management

- Pro Tool Reviews – Milwaukee Tools

- ToolGuyd – DeWalt Power Tools Review

- Toolbox Buzz – Ryobi Power Tools Review

- One Power Tool – Power Tool Batteries

- One Power Tool – Essential Power Tool Brands for Homeowners

- One Power Tool – Features of a Good Electric Hand Drill

- One Power Tool – Safely Removing a Stripped Screw

- One Power Tool – Safety Tips for Using Power Tools