Power Tool Usage & Projects Basics

Power Tool Basics

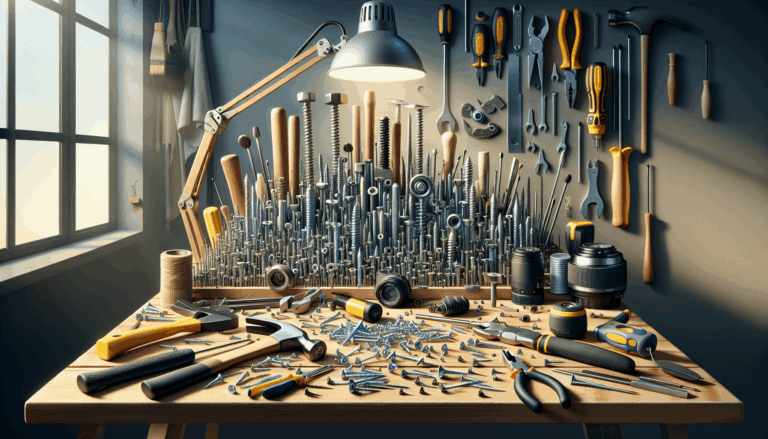

Power tools are indispensable in modern construction, woodworking, and home improvement projects. They are engineered to simplify tasks by utilizing an external power source—be it electricity, batteries, or compressed air—reducing manual effort and increasing efficiency. A solid understanding of their fundamental concepts, different types, and applications is crucial for both beginners and seasoned DIYers.

At their core, power tools encompass a wide variety of equipment designed for specific tasks. Whether drilling, cutting, grinding, or sanding, each tool plays a vital role in completing projects with precision and speed. Familiarity with basic power tools—such as drills, saws, sanders, grinders, and impact drivers—allows users to undertake a broad spectrum of tasks effectively.

For those seeking in-depth guidance, detailed tool reviews and expert tips are available on Power Tool Guides and Tips. What’s important is grasping the core functions and safety practices associated with each tool, ensuring productive and safe operation.

Types of Power Tools

1. Drills

Drills are perhaps the most versatile power tool, primarily used for drilling holes and driving screws. Cordless drills, favored for their portability, eliminate the need for cords and extension cables, making them ideal for on-the-go projects and tight spaces (Power Tool Guides and Tips). They come with various drill bits suited for wood, metal, or plastic, enabling a wide array of applications.

2. Saws

The saw family includes circular saws, jigsaws, and reciprocating saws. Circular saws excel at making straight cuts in lumber, flooring, or plywood. Jigsaws are used for curves and intricate cuts, while reciprocating saws handle demolition and rough cuts. Each saw type caters to different material types and project demands (Power Tool Guides and Tips).

3. Sanders

Sanders are designed for surface finishing—removing roughness, smoothing edges, and preparing surfaces for painting or varnishing. Types include orbital sanders, belt sanders, and detail sanders, each suited for specific tasks and materials (Power Tool Guides and Tips).

4. Grinders

Typically used for shaping or smoothing metal, concrete, or stone, grinders can also remove rust or paint. They come with various wheels and attachments tailored for grinding, cutting, or polishing (Power Tool Guides and Tips).

5. Impact Drivers

Impact drivers provide high torque, making screw driving easier and more effective, especially with stubborn fasteners. They outperform traditional drills in driving long or large screws and bolts, proving invaluable in heavy-duty construction or automotive work (Power Tool Guides and Tips).

Common Uses of Power Tools

Power tools enhance efficiency across a broad spectrum of activities:

- Construction and Carpentry: Faster, more precise cutting, drilling, and fastening accelerate building projects and custom woodworking.

- Home Improvement: Tasks like furniture assembly, hanging shelves, installing fixtures, or remodeling become more manageable.

- Automotive Repairs and Metalwork: Impact drivers, grinders, and drills streamline repairs, fabrication, and metal crafting.

Beginners should initially focus on basic tools such as drills and sanders, gaining confidence and skills before progressing to more advanced equipment. Proper understanding of each tool’s capabilities supports safe use and better project outcomes (Power Tool Guides and Tips).

Safety and Power Tool Maintenance

Maintaining your power tools is essential for their longevity and safe operation. Regular cleaning removes dust and debris that can impair functionality and cause overheating. Lubricating moving parts according to manufacturer instructions reduces wear, while inspecting cords and batteries prevents electrical hazards (Power Tool Guides and Tips). Proper storage in dry, secure environments protects against rust and accidental damage.

Safety begins with personal protective equipment—wear safety goggles, gloves, and hearing protection. Always verify that safety guards are in place before use and familiarize yourself with the manual. Avoid disabling safety features and stay focused on your task to prevent accidents (Power Tool Tips & Safety Guide).

Effective maintenance and adherence to safety protocols ensure your tools operate at peak performance and reduce injury risks, creating a safer workspace.

Power Tool Usage & Project Ideas

Harnessing power tools transforms DIY and home improvement from laborious to enjoyable. Starting with proper techniques—wearing protective gear and reading manuals—sets a foundation for safety and efficiency. For example, cordless drills are perfect for furniture assembly, shelving, or cabinetry. Circular saws accelerate wood cutting for flooring and decks, while rotary tools allow for detailed work in woodworking and metal projects.

Some beginner-friendly projects include:

- Building a Bookshelf: Use a cordless drill for drilling pilot holes and assembling shelves. Finish with stain or paint for a personalized touch.

- Creating Planter Boxes: Cross-cut lumber with a circular saw, assemble, and finish for a garden or patio feature.

- Installing Accent Walls: Use nail guns and sanders to attach and finish shiplap or reclaimed wood for a stylish interior feature (Power Tool Blog).

With the right tools and techniques, you can undertake a variety of projects, saving money and boosting your craftsmanship. Explore our blog for more project ideas and step-by-step guides to elevate your DIY game.

Power Tool Batteries

The performance and reliability of cordless tools heavily depend on the batteries they use. Understanding different battery types, proper maintenance, compatibility, and troubleshooting helps maximize their lifespan and efficiency.

Battery Types

- Nickel-Cadmium (NiCd): Durable but prone to memory effect and environmental concerns, less common today.

- Nickel-Metal Hydride (NiMH): Moderate capacity with fewer environmental issues, used less frequently now.

- Lithium-Ion (Li-ion): The industry standard, offering high energy density, lightweight, no memory effect, and longer run times.

Battery Care

Store batteries in a cool, dry place and avoid extreme temperatures. For Li-ion batteries, recharge when about 20% depleted rather than waiting until fully empty. Clean contacts regularly to ensure good connection. For extended storage, keep batteries at about 50% charge.

Compatibility & Troubleshooting

Always use batteries recommended by your power tool manufacturer. Mixing brands or voltages can damage the tool or void warranties. If a battery refuses to charge or hold a charge, examine contacts and charger function. Replacing worn-out batteries restores performance, but physical damage requires professional attention.

Proper battery maintenance ensures your cordless tools operate smoothly and reliably across numerous projects (Power Tool Batteries).

Power Tool Accessories

Maximize your power tools’ versatility with the right accessories. Essential add-ons include a variety of bits—drill, driver, masonry, or metal—tailored to specific tasks. Attachments like sanding pads, polishing wheels, cutting guides, and extension rods enable one tool to replace multiple specialized tools, saving space and cost.

Selecting high-quality accessories ensures durability and precision. For example, masonry bits for concrete work or saw blades suited for specific materials optimize results and extend tool life. Using dust collection attachments and extension cords can improve safety and accessibility during work.

Investing in comprehensive accessory kits provides convenience and versatility, allowing you to tackle diverse projects efficiently. Browse our recommended accessory options and guides at Power Tool Mastery Guide.

Choosing the Best Power Tool Brand

In a competitive market, selecting a reliable brand is key to ensuring quality, durability, and support. Leading brands like DeWalt, Makita, Milwaukee, Bosch, and Ryobi have established strong reputations through innovation, extensive product lines, and warranties (Power Tool Brand Reviews).

Consider factors such as battery ecosystems (e.g., Milwaukee’s M18), warranty coverage, tool variety, and customer service. For instance, Milwaukee’s interchangeable batteries across multiple tools enhance versatility, while DeWalt’s rugged construction suits professional environments.

Evaluate user reviews and expert comparisons to find the brand that best fits your specific needs—whether for heavy-duty construction or light DIY projects. Our detailed buying guides make choosing the right brand and model easier.

Power Tool Repair

Maintaining your power tools extends their lifetime and ensures safety. Common issues include tools that won’t start, burning odors, abnormal noises, loss of power, and worn bits or blades. Diagnosing these problems often involves checking batteries or electrical connections, cleaning components, and inspecting for damage.

Basic repairs such as replacing brushes, cleaning contacts, and lubricating moving parts can often be performed DIY. Regular cleaning, proper storage, and periodic component checks prevent many common failures. If your tool exhibits persistent issues or complex damage, professional repair or servicing is recommended (Power Tool Maintenance & Repair).

By staying attentive to wear and proactively addressing repairs, you keep your tools performing safely and reliably over time.

DIY Power Tool Projects

Engage creatively with your power tools by trying out simple DIY projects that can enhance your home and garden. Here are some ideas to inspire your next weekend:

- Build a Raised Garden Bed: Use a circular saw, drill, and sander to cut and assemble wood. Fill with soil and enjoy fresh vegetables or flowers (DIY Projects).

- Create a Custom Bookshelf: Cut, sand, and assemble shelves from wood, then finish with stain or paint for a personalized accent.

- Build a Patio Bench: Construct sturdy outdoor seating with wood planks, using your saws and drills, then seal for weather resistance.

- Install Floating Shelves: Use a stud finder and drill to attach brackets, creating sleek storage or display space.

- Make a Tool Organizer: Create a pegboard setup for your workshop tools, keeping everything organized and accessible.

These projects boost your DIY confidence, improve your living spaces, and make the most of your power tools. For detailed instructions, visit our DIY Projects section.

Sources

- OnePowerTool – Power Tool Guides and Tips

- OnePowerTool – Power Tool Maintenance & Safety

- OnePowerTool – Power Tool Usage & Projects

- OnePowerTool – Power Tool Batteries

- OnePowerTool – Power Tool Accessories

- OnePowerTool – Choosing the Best Power Tool Brand

- OnePowerTool – Power Tool Repair

- OnePowerTool – DIY Power Tool Projects