What are some safety tips for using an electric hammer drill?

Importance of Safety Gear

Wearing appropriate safety gear while using an electric hammer drill is crucial to protect yourself from various hazards. An electric hammer drill can generate significant force and produce flying debris, which can pose risks to the user’s health and safety.

- Eye Protection: Safety goggles are essential. They shield your eyes from flying debris, dust, and small particles that the drill might dislodge during use. According to the CDC, eye injuries are among the most common workplace accidents.

- Hearing Protection: Hammer drills can produce noise levels that exceed 85 decibels, which can lead to hearing loss with prolonged exposure. Earplugs or noise-canceling earmuffs are recommendations to mitigate this risk, as per the OSHA.

- Respiratory Protection: When drilling into concrete or similar materials, dust can become airborne. A dust mask or respirator can protect your respiratory system from inhaling harmful particles, as noted by the EPA.

- Hand Protection: Wearing gloves can prevent cuts and scrapes, especially when handling materials or tools. However, it’s important to use gloves that provide grip while allowing for flexibility to avoid accidental slips, as highlighted by safety guidelines from the NSC.

- Footwear: Steel-toed boots are recommended, as they protect your feet from heavy items that might be dropped. Proper footwear can also provide better grip on slippery surfaces, enhancing overall safety while operating power tools.

Ensuring you have the right protective gear when using an electric hammer drill significantly reduces the risk of injury. Always follow the manufacturer’s instructions and local safety regulations to maintain a safe working environment. For broader safety measures in DIY projects, consider reading more about general safety practices on our site.

Understanding the Manual

Thoroughly reading the user manual for your electric hammer drill is imperative for understanding its specific features and safety instructions. Each drill may come with unique functionalities, settings, and accessories designed for specific applications, which can optimize efficiency and results. Manufacturers emphasize that familiarizing oneself with the manual can significantly enhance user safety and appropriate tool handling.

Electric hammer drills are powerful tools that combine rotation with a hammering action, making them suitable for drilling into hard materials like concrete. Understanding how to use these features properly can protect users from accidents and injuries. For instance, the manual will typically outline essential safety precautions—like wearing protective gear, checking for electrical hazards, and maintaining a secure grip on the tool during operation. Neglecting these guidelines could lead to severe injuries or equipment damage, emphasizing the need for careful manual review.

Moreover, manuals often contain troubleshooting tips and maintenance advice crucial for extending the tool’s lifespan. Regular maintenance instructions can prevent common issues and ensure that your electric hammer drill operates effectively, saving time and potentially costly repairs in the future.

To learn more about the importance of using equipment safely, our article on the benefits of being informed offers insights that can enhance your overall safety while using power tools. Always prioritize reading the manual—it’s a small investment of your time for the safety and efficiency of your tasks.

Pre-Drill Inspection

A thorough pre-drill inspection is vital for ensuring the safety and efficiency of your drilling operations. Here are crucial steps to follow:

- Conduct a Visual Inspection: Before starting, visually inspect the drill and equipment for any signs of damage, wear, or defects. Ensure all parts, including drill bits and safety guards, are in good condition and free of debris.

- Check Safety Equipment: Ensure that all safety gear, including helmets, goggles, and gloves, is available and undamaged. Double-check that emergency equipment, such as fire extinguishers and first-aid kits, are easily accessible and fully stocked.

- Evaluate the Work Area: Clear the work area of unnecessary obstacles, and ensure that there is adequate lighting. Inspect the ground surface for stability to prevent slips or falls during operations.

- Assess Environmental Conditions: Be mindful of weather conditions that could impact safety, such as high winds or rain. Take measures to secure the area against adverse conditions.

- Review Operating Procedures: Confirm that all personnel involved in the drilling operation are aware of and understand the safety protocols and the specific operation plan to ensure compliance with safety regulations.

- Test Equipment Functionality: Conduct a functionality test on the drill and other equipment to ensure everything operates smoothly.

- Communicate Risks and Responsibilities: Hold a pre-drill meeting to discuss roles, responsibilities, and risks associated with the operation.

For comprehensive guidelines and further reading on workplace safety, check resources like OSHA’s General Duty Clause and equipment-specific safety guidelines.

Workpiece Security

To ensure safety during drilling, it is crucial to secure the workpiece effectively to prevent any movement, which can lead to accidents or injuries. Here are several techniques that can be employed:

- Clamping: Use sturdy clamps to secure the workpiece to the work surface.

- Vise Use: For smaller pieces, a bench vise provides excellent stability.

- Double-Sided Tape: For lighter materials, applying double-sided tape can provide additional grip.

- Drilling Straight Through: Drill straight through the workpiece into a sacrificial board located underneath.

- Using Dowels or Pins: Inserting dowels can help maintain the workpiece’s position.

- Pre-Drilling: Small pilot holes can help guide the drill bit.

- Weighted Supports: Using weights can further secure larger pieces.

Employing these methods enhances safety and improves the accuracy of the drilling task. For further guidance on improving safety while engaging in woodworking or metalworking, check out articles such as How to Choose the Right Drill for Your Project and 5 Quick & Simple Mental Exercises to Try During Stressful Times.

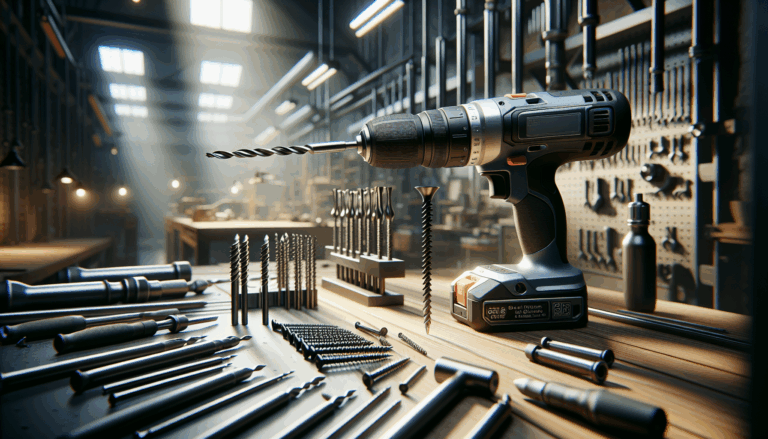

Choosing the Right Drill Bit

The selection of the appropriate drill bit for your project is crucial for enhancing safety and operational efficiency. Using the correct drill bit minimizes risks such as breakage or accidents from using inappropriate tools. For example, masonry bits are optimized for concrete, while wood drill bits are intended for softer woods. Misuse can lead to excessive pressure on the tool, resulting in potential injury.

Moreover, utilizing specialized drill bits can greatly improve performance. For instance, titanium-coated bits offer longevity and quicker drilling speeds due to decreased friction. Research indicates that the right type of bit can reduce heat generation, thus prolonging tool and bit lifespan. Furthermore, proper bit selection ensures cleaner cuts and precise fits, essential for both construction projects and home improvements.

For more insights into optimizing your tool use, check out our article on 5 Quick Simple Mental Exercises to Try During Stressful Times.

Gradual Speed Increase

To achieve control and precision during drilling tasks, it is essential to adopt a technique of gradually increasing the drill’s speed. This method enhances the accuracy of the drilling operation by facilitating better handling of the drill. Starting at a low speed allows making initial contact with the material.

Research indicates various drilling types benefit from a controlled speed increase, as it minimizes heat generation and prolongs the lifespan of the drill bit. Implementing this technique leads to cleaner finishes and reduces the risk of material splintering, ensuring high-quality outcomes in your projects.

For more tips on drilling and tool usage, check out our article on effective drilling techniques.

Firm Grip Technique

Maintaining a secure grip on the drill is crucial for safety and performance. Here are several key considerations to ensure proper handling:

- Use the Right Technique: Wrap your fingers around the handle securely, and maintain a strong stance for balance.

- Watch for Slippery Conditions: Ensure your hands are clean and dry to prevent slips.

- Maintain Equipment: Regularly check bits for wear; dull components can cause slips.

- Practice Control: Begin drilling at a lower speed for better management.

- Secure the Workpiece: Use clamps or a vice to reduce the chance of the material moving unexpectedly.

By focusing on these strategies, you can significantly enhance safety and effectiveness while working with drills. For more detailed safety tips regarding tool usage, check out our article on tool safety best practices.

Depth Gauge Utility

A depth gauge is an essential tool in construction, providing critical benefits for achieving consistent depths and enhancing safety on-site. It assists in accurately measuring depths, ensuring adherence to design specifications and local regulations. Maintaining precise depths helps prevent costly mistakes and mitigates risks associated with structural failures.

Using a depth gauge minimizes the chance of over-excavation, which reduces the likelihood of workplace accidents. Regular use promotes efficiency on construction sites, streamlining processes by providing clear depth indicators.

Incorporating a depth gauge into daily construction practices elevates both safety and work quality. For additional insights on improving construction methods, visit our other articles here.

Power Cord Management

To minimize tripping hazards while using power tools, consider these strategies:

- Use Cord Covers: Invest in cord covers to keep cords flat and reduce tripping risks.

- Plan Your Workspace: Organize tools close to power outlets to minimize cord lengths.

- Elevate Cords: Use hooks or clips to keep cords off the ground.

- Utilize Extension Cords Wisely: Ensure extension cords are rated for your tools and positioned safely.

- Practice Good Cord Management: After use, store cords neatly to prevent kinks and tangles.

- Regularly Inspect Cords: Check for wear and damage before each use.

- Transparent Markings: Use bright tape to mark cords crossing pathways.

By implementing these strategies, you can create a safer work environment while protecting your power tools from damage. For further safety tips, explore our article on tool safety best practices.

Proper Power Disconnection

To safely disconnect the power source from electrical tools and prevent accidental start-ups, follow these essential steps:

- Preparation: Ensure you have insulated gloves and goggles. Check for potential hazards around the tool.

- Turn Off the Tool: Switch off the power tool using its main power switch.

- Unplug the Tool: After shutting it down, unplug from the electrical outlet.

- Secure the Power Source: Lock the circuit breaker switch in the off position if applicable.

- Perform Lockout/Tagout (LOTO): Lock or tag the breaker to prevent others from turning it back on.

- Wait and Verify: Allow residual energy to dissipate, then verify that the tool is completely off.

- Conduct Inspections: Inspect the tool for any damage before maintenance.

These steps ensure the safety of users and the integrity of the equipment. For more detailed information on electrical safety practices, refer to this comprehensive guide on electrical safety from the NFPA. For insights on maintaining tools in safer working conditions, consider reading about safety protocols on our blog.

Sources

- CDC – Safety and Health Topics

- EPA – Respiratory Protection

- Forbes – Task Automation Insights

- NSC – Personal Protective Equipment

- OSHA – Occupational Noise Exposure

- One Power Tool – Benefits of Being Informed

- One Power Tool – General Safety Practices

- One Power Tool – How to Choose the Right Drill

- One Power Tool – Mental Exercises for Stress

- NFPA – Electricity Safety