What are the best car safety tools for power tool use?

Introduction: Importance of Car Safety Tools for Power Tool Use

Using power tools in a vehicle environment carries significant risks, emphasizing the need for the appropriate safety tools and preparedness. Power tools, such as electric drills and impact wrenches, can lead to serious injuries if not handled with care. According to the National Institute for Occupational Safety and Health (NIOSH), improper use or lack of safety equipment can result in accidents ranging from minor cuts to severe lacerations or amputations.

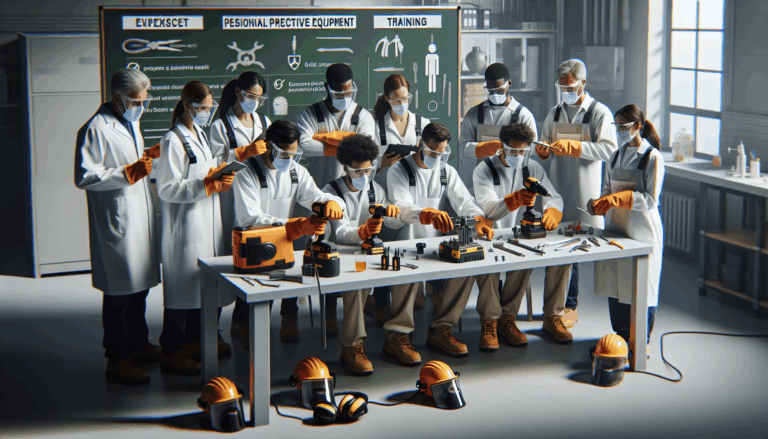

Key safety tools and equipment include safety glasses, gloves, ear protection, and dust masks, which are critical in mitigating these risks. For instance, eye protection is essential to prevent flying debris from causing eye injuries while working with power tools [Source: Safety+Health Magazine].

Moreover, preparedness entails not only having the right tools but also understanding proper operation procedures, maintenance of tools, and recognizing potential hazards in the workspace. Training on the correct usage of tools can greatly reduce the likelihood of accidents, encompassing both theoretical knowledge and practical skills [Source: One Power Tool].

In summary, equipping oneself with the right safety tools and preparing adequately can dramatically decrease risks associated with using power tools in vehicles, ensuring a safer working environment.

Safety Glasses: Protecting Your Vision

Safety glasses are a vital component in any arsenal of power tool safety tools. They serve to protect one’s eyes from flying debris and potential hazards associated with cutting or grinding tasks. Regular glasses do not offer sufficient protection; hence, it’s essential to invest in high-quality safety glasses that comply with ANSI (American National Standards Institute) standards [Source: ANSI].

When selecting safety glasses, consider features such as side shields for additional coverage and anti-fog coatings to maintain visibility. Wearing safety glasses significantly reduces the chances of eye injuries, which can lead to long-term vision problems [Source: Safety+Health Magazine].

Ear Protection: Safeguarding Your Hearing

Protecting your ears from loud noise exposure while using power tools is crucial for preserving your hearing. There are different types of ear protection available:

- Earplugs: Small devices that can be inserted into the ear canal, achieving high levels of noise reduction with some foam earplugs providing up to 33 dB NRR [Source: NCBI].

- Earmuffs: Feature sound-dampening cups covering the ears, offering a similar NRR. Some models come with electronic noise-canceling technology [Source: CDC].

- Industrial Headsets: These provide superior noise reduction while enhancing situational awareness through electronic features [Source: Safety + Health Magazine].

- Custom Molded Earplugs: Made from impressions of your ears for a personalized fit and excellent noise attenuation [Source: ASHA].

- Smart Hearing Protection: High-tech devices allowing users to customize sound amplification and noise reduction levels [Source: OSHA].

Selecting suitable ear protection can significantly minimize the risk of hearing loss during prolonged exposure to power tools.

Dust Mask: Filtering Hazardous Particles

Wearing a dust mask during power tool use is crucial for respiratory safety. Power tools generate fine particles, wood dust, or metal shavings that can be damaging when inhaled. Prolonged exposure can lead to serious respiratory diseases [Source: CDC].

Dust masks rated N95 or higher filter at least 95% of airborne particles, effectively minimizing inhalation of hazardous materials [Source: OSHA]. Ensuring a proper fit and regular replacement of masks is important for optimal protection.

Gloves: Ensuring Hand Safety and Grip

Gloves are another essential piece of safety equipment designed to protect hands from cuts, abrasions, and chemical exposure. When selecting gloves, it’s vital to choose the right material for the task, as some tasks may involve sharp edges or hazardous substances. Materials such as leather, nitrile, and vinyl are commonly used, depending on the specific applications [Source: Safety+Health Magazine].

Ensuring gloves fit properly is crucial for maintaining both safety and dexterity, allowing for a secure grip on tools without compromising hand protection. For detailed hand safety tips, check out our article on safety tips for hand protection.

Fire Extinguisher: Emergency Preparedness

Having a fire extinguisher readily available when operating power tools is critical for ensuring safety during emergencies. Power tools can pose a fire risk due to sparks or flammable materials in the work area. The National Fire Protection Association (NFPA) emphasizes using the correct extinguisher type for the specific fire risks present in your workspace.

Regular inspections and placement near the work area ensure readiness, while training in its proper use enhances preparedness [Source: Ready.gov].

First Aid Kit: Essential for Minor Injuries

A well-equipped first aid kit is vital for addressing minor injuries encountered while using power tools. Essential supplies should include:

- Adhesive bandages

- Sterile gauze pads

- Antiseptic wipes

- Hydrogen peroxide or alcohol swabs

- Tweezers and scissors

- Elastic bandage

- Burn cream or aloe vera gel

- Ice packs

- Pain relievers

- Disposable gloves

Regularly checking and replenishing your first aid supplies will ensure effectiveness in emergencies and minimize the risks associated with minor injuries.

Power Tool Brands: Choosing Reliable Options

When selecting power tool brands that emphasize safety and reliability, consider factors such as:

- Reputation and Reviews: Brands like DeWALT, Bosch, and Makita are often praised for their durability and safety features.

- Safety Certifications: Tools are required to meet ANSI and UL safety standards [Source: ANSI].

- Feature Evaluation: Look for safety features, such as lock-off switches and safety guards.

- Warranty and Support: Strong warranties reflect brand confidence, like those offered by Ryobi and Hilti.

- Recommendations from Professionals: Consult industry experts for brand suggestions.

By focusing on these criteria, you can select power tool brands that not only deliver on performance but also provide safety [Source: Essential Power Tool Brands for Homeowners].

Power Tool Maintenance: Ensuring Equipment Efficiency

Regular maintenance of power tools is essential for safe and efficient operation. Key maintenance tips include:

- Cleaning tools after use

- Performing regular inspections

- Storing tools properly

- Sharpening blades and bits

- Lubricating moving parts

- Checking and replacing batteries as needed

- Following manufacturer’s instructions

- Using tools as intended

By adhering to maintenance best practices, you can prolong the life of your tools and reduce the risk of injuries.

Conclusion: Prioritizing Safety in Car Projects

Prioritizing safety while using power tools in vehicle projects is crucial to prevent accidents and injuries. Embracing a culture of vigilance and preparedness is key. Always wear appropriate personal protective equipment (PPE) and ensure a clear understanding of all tools and their safety guidelines.

Regular inspections of tools, understanding emergency procedures, and maintaining an organized workspace can significantly reduce the likelihood of accidents. Continuous education and adherence to safety practices are your best defense against potential mishaps in any project using power tools [Source: Importance of Safety When Using Power Tools].

Sources

- ASHA – Custom Molded Earplugs

- ANSI – American National Standards Institute

- CDC – Protecting Against Dust and Particulates

- CDC – Hearing Protection

- NCBI – Earplugs

- NFPA – National Fire Protection Association

- One Power Tool – Essential Power Tool Brands for Homeowners

- One Power Tool – Importance of Safety When Using Power Tools

- One Power Tool – Safety Tips for Using an Electric Hammer Drill

- Ready.gov – Fire Safety

- Select Safety Products – Classification of Fire Extinguishers

- Safety + Health Magazine – Choosing Hearing Protection

- Safety+Health Magazine – Tips to Prevent Eye Injuries

- OSHA – Smart Hearing Protection

- OSHA – Respiratory Protection