What are the best power tools to use when working with plywood?

Choosing the Right Power Tools for Plywood Projects

Using the right power tools for plywood projects is essential for ensuring cutting precision and achieving professional results. The choice of tools can dramatically influence the quality of your work. Circular saws, for instance, are ideal for straight cuts and can handle thick plywood, while jigsaws are better suited for intricate shapes and curves. Properly selected tools reduce the risk of splintering, which is crucial for maintaining clean edges [Source: One Power Tool].

Factors like blade type and speed settings must align with your specific plywood project to optimize results. High-quality, sharp blades designed for plywood ensure smoother cuts and minimize the stray fibers that result from rough cuts. Additionally, utilizing tools with adjustable speed helps adapt to the density of the plywood, further promoting precision [Source: One Power Tool].

Investing in the right power tools not only enhances accuracy but also streamlines the workflow, saving time and effort while improving overall safety during projects. By following best practices and selecting the appropriate tools, you can confidently tackle various woodworking tasks, resulting in finishes that reflect a high standard of craftsmanship.

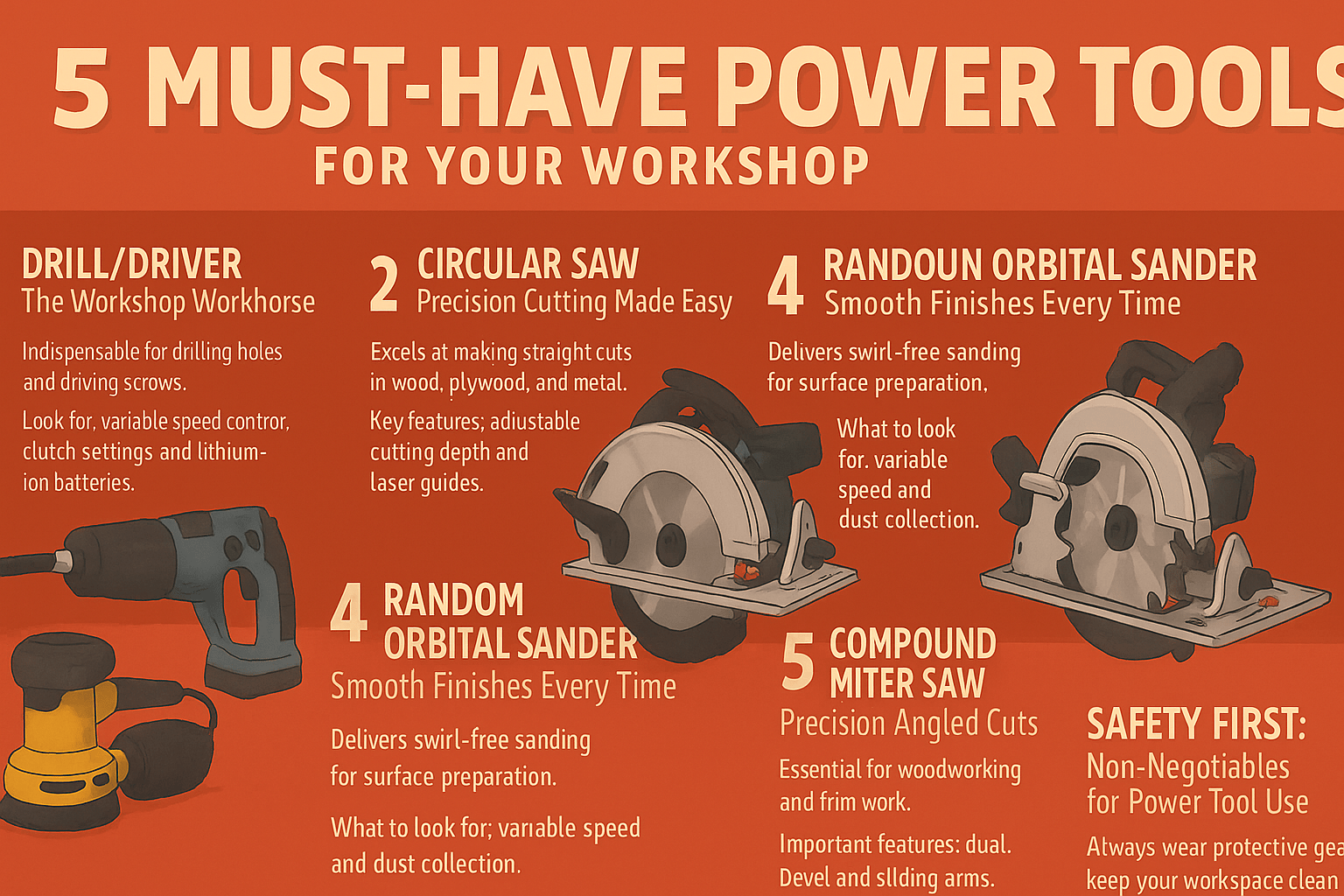

Essential Features of Circular Saws for Plywood Projects

Circular saws are indispensable tools for any woodworking project involving plywood due to their versatility, power, and ability to make straight cuts with precision. When selecting a circular saw for plywood projects, consider the following essential features:

- Blade Size: Most circular saws come with 7 1/4-inch blades, ideal for cutting through standard plywood thickness.

- Power Rating: Look for a saw with a minimum of 15 amps to ensure it can handle tough cuts without bogging down.

- Bevel Capacity: A saw with a bevel capacity allows you to make angled cuts.

- Ease of Use: Features such as a lightweight design and an ergonomic handle improve user-friendliness.

- Dust Blower or Vacuum Port: Helps keep the cutting line clear for safety and accuracy.

- Safety Features: Look for guards that reduce the risk of blade exposure.

- Corded vs. Cordless: Cordless models offer mobility, while corded provides reliable power.

- Adjustable Speed: Advanced models allow users to adjust the RPM for different materials.

For a deeper understanding of how to use power tools safely and effectively, check out our guide on power tool usage projects and explore essential features of electric drills in our article on what are the features of a good electric hand drill.

Advantages of Using Table Saws for Plywood Cutting

A table saw is a game-changer for cutting plywood, significantly enhancing both precision and stability. Here are some key benefits:

- Enhanced Stability: A stable platform minimizes the risk of movement during cutting.

- Precision Cuts: Allows for precise adjustments in blade height and angle.

- Control Over Cuts: The motorized function maintains consistent speed, leading to smoother cuts.

- Ease of Use: Requires less physical force compared to manual saws.

For those new to table saws or looking to improve their technique, understanding proper usage and setup can further enhance the results. Explore best practices in our article on power tool usage basics for more insights.

Utilizing Jigsaws for Intricate Cuts

The jigsaw is a versatile power tool ideal for making intricate and curved cuts in plywood. Its design allows for easy maneuverability, making it a favorite among woodworkers for crafting detailed shapes and patterns. To achieve the best results, selecting the right blade is crucial.

For cutting plywood, choose a blade specifically designed for wood, such as a T-shank blade, which provides better grip and stability. Blades with a higher tooth count help in making smoother cuts and reducing splintering [Source: One Power Tool].

When working on intricate patterns, a narrower blade will enable you to navigate tighter curves with ease. Additionally, always consider using a jigsaw with variable speed settings to enhance the quality of the cut.

Benefits of Routers in Woodworking

Routers are incredibly versatile tools in woodworking, serving multiple purposes that significantly enhance the quality and aesthetics of your projects. One of their primary uses is for shaping plywood. By utilizing various bits, routers can create smooth, curved edges, essential for crafting furniture and decorative panels [Source: One Power Tool].

Moreover, routers excel at creating both straight and rounded profiles, improving the visual quality and providing safer edges. Understanding the best practices for router usage, including selecting the right bits and maintaining safe operation, is crucial for achieving the desired results while minimizing injury risks.

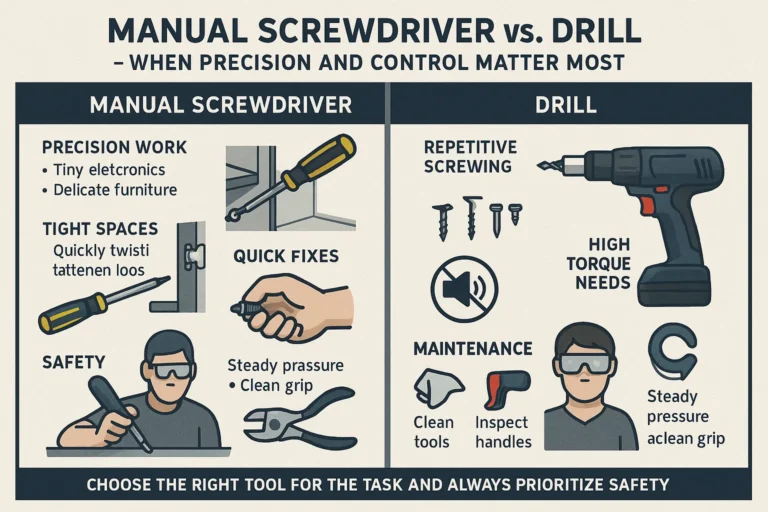

Tips for Using Power Drills Effectively

Power drills play a crucial role in woodworking, enabling precise drilling and fastening tasks essential for crafting furniture and cabinets. For accurate results, ensure that the drill bit is properly aligned with the workpiece to minimize errors [Source: One Power Tool].

Investing in high-quality drill bits made from durable materials can prevent wood splintering and provide a smoother finish. Techniques such as starting at a slow speed and gradually increasing power can enhance control and precision.

Using Random Orbital Sanders for a Smooth Finish

Using a random orbital sander offers numerous benefits for achieving a smooth finish on plywood projects. Many models are equipped with dust collection systems that significantly reduce airborne particles, improving air quality.

Additionally, adjustable speed settings allow users to tailor the sanding speed to different applications. The dual orbiting motion minimizes swirl marks and provides a uniform surface finish, ideal for woodworking projects [Source: One Power Tool].

Miter Saws for Precise Angles

Miter saws are essential tools for making precise angled cuts. Their utility lies in achieving accurate bevel and compound cuts, crucial for framing and furniture making. For efficiency, the RPM of a miter saw significantly influences its cutting performance. Higher RPMs facilitate smoother cuts, reducing the likelihood of splintering.

For comprehensive guidance on the effective use of power tools, including miter saws, visit our article on power tool usage projects.

Safety Guidelines in Woodworking

Using the right tools and adhering to safety guidelines is crucial for enhancing woodworking skills and achieving professional results. Proper tools, such as high-quality saws and drills, ease the process and improve precision.

Always wear protective gear and implement safety measures, such as using non-sparking tools in hazardous environments. A commitment to safety protects the woodworker and contributes to a more focused work ethic [Source: One Power Tool].

Conclusion

Combining suitable tools with rigorous safety practices is fundamental in producing quality woodworking results, maximizing the skills and outcomes of projects.