What are the best practices for maintaining woodwork hand tools?

Introduction to Woodwork Hand Tools Maintenance

Maintaining your woodwork hand tools is essential for enhancing their performance and extending their lifespan. Proper care ensures that tools remain in optimal working condition, which directly affects the quality of your projects. Regular upkeep, such as cleaning and sharpening, significantly enhances the efficiency of tools. For instance, a sharp chisel cuts cleaner and requires less force, preventing strain and improving the overall quality of woodworking tasks [Source: Wood Magazine].

Cleaning and Rust Prevention

Maintaining your tools not only preserves their functionality but also prevents rust and prolongs their lifespan. Here are effective techniques and practices to clean your tools and avoid rust damage:

- Regular Cleaning: After use, always wipe down your tools with a clean, dry cloth to remove moisture and dirt. A soapy water solution can be used for stubborn grime, but ensure tools are dried thoroughly afterward [Source: Wood Magazine].

- Use a Rust Preventive: Apply a light coat of oil, such as mineral oil or three-in-one oil, on metal surfaces of tools to form a protective barrier against moisture [Source: One Power Tool].

- Store Properly: Store tools in a dry environment. Tools that are not frequently used can be wrapped in oil-soaked rags to provide extra protection [Source: One Power Tool].

- Use Desiccants: Place silica gel packets in tool storage areas to absorb moisture, particularly valuable in damp climates [Source: One Power Tool].

- Inspect Regularly: Periodically check tools for any signs of rust or wear. Early detection allows for quicker restoration [Source: One Power Tool].

Sharpening Techniques

Maintaining sharp cutting tools is essential for both safety and efficiency in woodworking. Dull tools can lead to accidents due to increased force needed during use. For chisels, honing the blades at a consistent angle is crucial. Use a bench grinder to establish the primary bevel, then finish with a whetstone [Source: The Wood Whisperer].

Saws benefit from periodic sharpening to maintain tooth geometry. Using file guides ensures consistency while sharpening. Investing time in sharpening your tools will lead to cleaner cuts and a more enjoyable working experience. For further insights into tool maintenance, explore our article on best practices for avoiding damages during power tool usage.

Handle Care and Maintenance

The comfort and functionality of tool handles are essential for effective use. Here’s a comprehensive guide to handle care:

- Inspecting Tool Handles: Regularly check for signs of wear, cracks, or splintering that could affect grip and control. Clean handles thoroughly to maintain an effective grip [Source: CDC NIOSH].

- Restoring Tool Handles: For wooden handles, sand rough spots and apply linseed oil to enhance durability. Rubber or plastic handles can be repaired using grip tape [Source: Popular Woodworking].

- Protecting Tool Handles: Store tools in a dry environment to prevent deterioration. Adding protective grips can improve comfort during prolonged use.

Maintaining comfortable handles leads to better performance and less risk of accidents.

Proper Storage Solutions

Storing tools in clean and dry conditions is essential for maintaining their functionality. Exposure to moisture can lead to rust while dirt and debris compromise performance. Here are essential storage tips:

- Use Vertical Storage Solutions: Utilize wall-mounted pegboards to keep tools visible and accessible.

- Categorize by Use: Group tools according to function and store them in clearly labeled bins or drawers [Source: Woodworkers Source].

- Regular Maintenance: Conduct periodic checks to ensure tools remain clean and in good condition [Source: One Power Tool].

- Utilize Toolboxes and Bags: Invest in high-quality, waterproof tool storage for smaller tools.

- Implement a Routine: Set a schedule for organizing tools to ensure everything stays in its designated place.

By following these practices, you enhance not only your safety during projects but also the longevity of your tools.

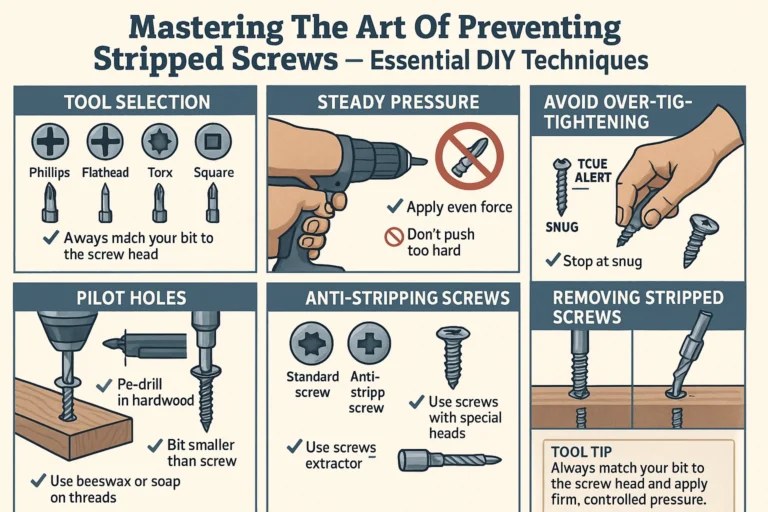

Preventing Stripped Screws

To prevent stripped screws, implement these strategies:

- Correct Screwdriver Selection: Use the right type of screwdriver that matches the screw head to minimize slippage Source: One Power Tool.

- Pilot Hole Sizing: Drilling a pilot hole first can help when driving screws into dense materials.

- Adequate Lubrication: Lubricate screws before insertion to reduce friction. Source: One Power Tool.

- Controlled Torque: Adjust torque settings on your power drill to prevent over-driving the screw Source: One Power Tool.

- Keep Tools Maintained: Regularly check drill bits and screwdrivers for wear and replace them as necessary Source: One Power Tool.

By following these guidelines, you will significantly decrease the likelihood of stripped screws while enhancing project effectiveness.

Conclusion: Longevity of Woodwork Hand Tools

By prioritizing care for your woodwork hand tools through regular maintenance, cleaning, and the right storage practices, you enhance their performance and ensure they serve you well over the long haul. Whether it’s keeping tools rust-free, sharp, or ensuring the comfort of handles, each aspect contributes to a more efficient and safe working environment.

Sources

-

- CDC NIOSH – Ergonomic Tool Design

- Fine Woodworking – 10 Tips for Hand Tool Care

- Wood Magazine – How to Clean Woodworking Tools

- Wood Magazine – Sharpening Blades and Chisels

- Popular Woodworking – Keep Your Tools in Top Shape

- The Wood Whisperer – How to Sharpen Hand Tools

- ToolSelect – How to Extend the Life of Your Tools

- One Power Tool – Power Tool Usage

- One Power Tool – Power Tool Usage Basics

- One Power Tool – Best Practices to Avoid Stripping Screw Heads

- One Power Tool – Essential Power Tool Brands for Homeowners

- Woodworkers Source – Tool Storage Solutions

- One Power Tool – Safety Tips for Using an Electric Hammer Drill