What are the best practices to avoid stripping screw heads with power tools?

Introduction to Preventing Stripping Screw Heads with Power Tools

Preventing screw head stripping is crucial for maintaining the efficiency and longevity of power tools. Strip damage can compromise the fastening strength, leading to weak connections and a higher risk of tool malfunction. This problem often arises from using the wrong type of bit for the screw, applying excessive torque, or not aligning the screw properly before driving. To avoid stripping screws, choose the correct bit size and type that matches the screw head. For example, use a Phillips head for Phillips screws and a flathead for slotted screws. Moreover, using a torque-controlled drill can help regulate the force applied, minimizing the risk of overdriving screws, which can cause the heads to strip. Additionally, starting with pilot holes can guide the screw into the material correctly, reducing friction and preventing stripping. A well-fastened screw not only enhances the integrity of the assembly but also improves the tool’s effectiveness, saving time and materials in your projects.

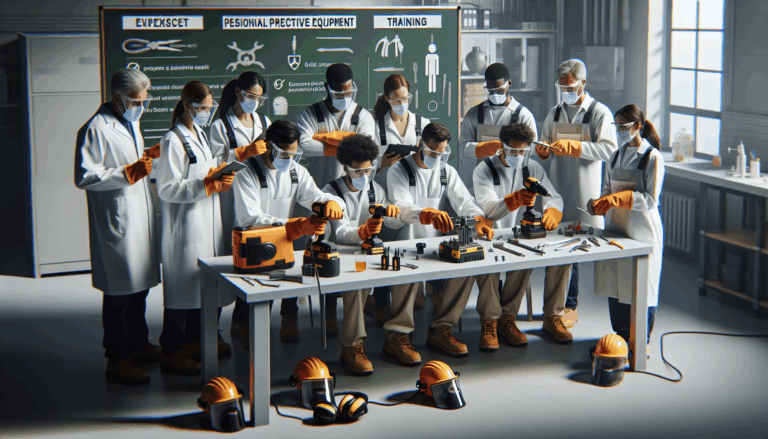

Understanding Your Power Tool

To effectively familiarize yourself with your power tool’s features and limitations, start by thoroughly reading the owner’s manual. The manual provides essential information about the tool’s specifications, safety guidelines, and operational capabilities. Familiarizing yourself with safety features, such as emergency shut-off mechanisms and protective gear requirements, is crucial for safe usage. Next, explore the manufacturer’s website for additional resources, including video tutorials and FAQs that can deepen your understanding of the tool’s functionalities. Practicing with the tool under supervision or in a controlled environment allows you to understand its handling and limitations firsthand. Moreover, utilizing your tool’s safety features is equally important. Regularly inspect the tool for any wear and tear, and follow maintenance guidelines to enhance performance and longevity.

Choosing the Right Screw and Screwdriver Bit

When selecting screws and screwdriver bits for optimal performance, it’s essential to understand the various types available and their intended uses. Wood screws are designed specifically for fastening wood materials, featuring a sharp tip and coarse threads. Metal screws are used for metal-to-metal applications, often with finer threads. Self-tapping screws create their own threads as they are driven into the material. Choosing the right screw type is critical to match the material being worked on. Ensuring a proper fit between screw and bit is equally important. A mismatched bit can lead to ineffective driving and potential damage to both the screw and material. Always choose a screwdriver bit that fits snugly with the screw head type, and consider using power tools with adjustable torque settings for greater precision.

Maintenance Tips for Power Tool Longevity

Regular maintenance of power tools is crucial for preserving their functionality and extending their lifespan. Key maintenance practices include cleaning, lubrication, inspection, and proper storage. After each use, tools should be cleaned to remove dust and debris, which prevents rust and corrosion. Proper lubrication minimizes friction between moving parts, and regular inspections help identify signs of damage or wear. Lastly, store tools in a dry, clean environment to prevent damage. Implementing these practices will significantly enhance the longevity and performance of your power tools.

Correct Technique in Using Power Tools

To avoid damaging screw heads while using power tools, follow these essential tips. Always select a screwdriver bit that perfectly fits the screw head to prevent slipping and stripping. For drills and impact drivers, adjust the torque settings before starting, and apply consistent pressure while driving the screw. Drill pilot holes when working with wood to guide the screws and ensure precise alignment. Avoid over-tightening and check for debris before inserting screws to minimize potential damage.

Importance of Quality Screws and Bits

Using high-quality screws and bits can significantly enhance the success of your projects. High-quality screws manufactured from materials like stainless steel resist corrosion and wear, promoting longevity. Quality bits provide better fit and grip with screw heads, reducing cam-out and stripping during use. By investing in premium screws and bits, you not only secure the structural integrity of your project but also enhance overall productivity and efficiency.

Practicing Patience and Safety

Taking your time when working with power tools significantly enhances safety and effectiveness. Rushing tasks can lead to accidents, so engage in careful planning and use appropriate safety equipment, such as goggles and gloves. Training in proper tool handling and maintenance is crucial. Always prioritize safety and take the time needed to use power tools responsibly to protect yourself and others around you.

Strategies for Handling Stripped Screws

When dealing with stripped screws, several effective methods can help ensure successful removal. Techniques include using a rubber band over the stripped head for grip, screw extractors for better rotation, left-handed drill bits to catch and remove the screw, and Dremel tools to create new slots for standard screwdrivers. Depending on the context and severity of stripping, utilizing the right method can save time and effort in removing problematic screws.

Conclusion and Maintenance Guide Recap

Ultimately, paying careful attention to the maintenance of power tools and adopting best practices can significantly enhance their functionality and longevity. Regular cleaning, proper storage, and quality materials not only improve tool performance but also ensure safer and more effective usage. By understanding and implementing these guidelines, you can foster a productive and safe work environment.

Power Tool Best Practices Quiz and Recommended Products

Consider participating in a quick interactive quiz designed to assess your current habits and provide suggestions for value-adding improvements in your tool usage. Moreover, integrating recommended products like omega-3 supplements, vitamin D3, and sleep aids can enhance overall well-being while you work on your projects. For more insights on tools and techniques, explore our blog section.