What is the maintenance and proper storage procedure for power tools?

The Ultimate Guide to Power Tool Maintenance and Storage

Power tools are essential for DIY projects and professional jobs, but their performance and lifespan depend on proper care. Regular maintenance and smart storage practices can prevent costly repairs, ensure safety, and extend your tools’ working life. Follow this comprehensive guide to keep your tools in peak condition.

Why Proper Maintenance Matters

Maintaining your power tools isn’t just about cleanliness – it’s about performance, safety and protecting your investment. Well-maintained tools operate more efficiently, reduce accident risks, and maintain their resale value. According to Pro Tool Reviews, regular maintenance can extend a tool’s lifespan by 50% or more.

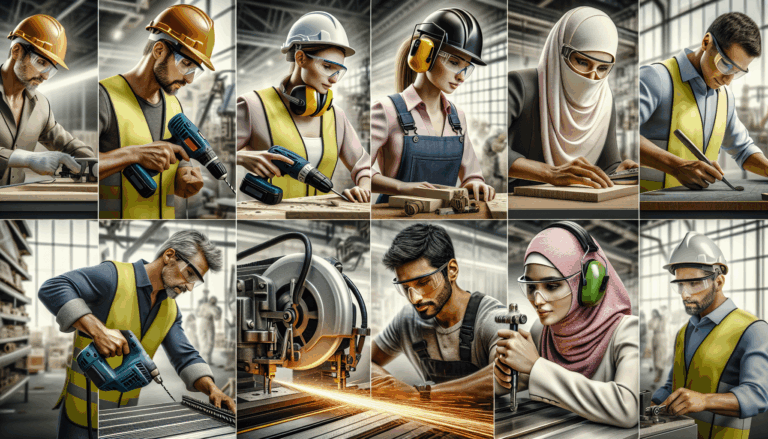

Essential Power Tool Maintenance Steps

1. Cleaning Your Tools

After each use, remove dust and debris that can damage components. Use compressed air for vents and a soft brush for crevices. For stubborn grime, Family Handyman recommends using a mild detergent solution, but avoid soaking electrical parts.

2. Lubricating Moving Parts

Friction causes premature wear. Apply manufacturer-recommended lubricant to gears and bearings, being careful not to over-lubricate. As noted by Popular Mechanics, excess lubricant attracts dust that can clog mechanisms.

3. Blade and Bit Care

Dull cutting tools strain motors and produce poor results. Inspect blades after each use, sharpening or replacing when needed. This Old House suggests storing bits in labeled cases to prevent damage.

4. Electrical Safety Checks

Inspect cords and plugs for damage before each use. The Occupational Safety and Health Administration (OSHA) warns that faulty electrical components cause numerous workshop accidents annually.

5. Battery Maintenance

For cordless tools, follow charging guidelines and store batteries at 40-60% charge in moderate temperatures. Bob Vila notes that proper battery care can triple their usable life.

Smart Storage Solutions

1. Climate Control

Store tools in dry, temperature-controlled spaces. The National Association of Certified Home Inspectors reports that humidity causes most tool corrosion issues.

2. Protective Cases

Use original cases or invest in quality toolboxes. Foam inserts prevent damage during transport and storage.

3. Wall Organization

Pegboards and wall racks keep tools accessible while preventing damage from stacking. Fine Homebuilding recommends this approach for small workshops.

4. Cord Management

Use Velcro straps or reels to prevent tangles and kinks that can damage wiring over time.

5. Seasonal Storage

For long-term storage, apply rust inhibitor to metal parts and remove batteries. The Consumer Reports tool testing team suggests checking stored tools quarterly.

Final Recommendations

Establish a regular maintenance schedule, referring to manufacturer guidelines for each tool. Well-cared-for equipment performs better, lasts longer, and maintains its value. As professional contractors quoted in Tools of the Trade magazine emphasize, “Your tools are only as good as the care you give them.”

Sources

- Pro Tool Reviews – Power Tool Maintenance Guide

- Family Handyman – Cleaning Power Tools

- Popular Mechanics – Tool Lubrication Tips

- This Old House – Workshop Organization

- OSHA – Electrical Safety Standards

- Bob Vila – Battery Maintenance

- NACHI – Tool Storage Recommendations

- Fine Homebuilding – Workshop Layouts

- Consumer Reports – Tool Testing

- Tools of the Trade – Professional Maintenance Tips