What safety equipment should I use when using power tools?

Eye Protection: Safeguard Your Vision

When operating power tools, wearing appropriate eyewear is crucial to protect your eyes from flying debris and harmful particles. According to the American Optometric Association, safety glasses or goggles should be worn whenever there is a risk of eye injury, particularly in environments where power tools are in use. These protective lenses can shield against high-velocity impacts, dust, and harmful chemicals, reducing the risk of eye injuries, which are prevalent in both professional and DIY settings. For instance, it’s estimated that around 2,000 workplace eye injuries occur every day, many of which could be prevented with proper eye protection like safety goggles or safety glasses.

Different types of safety eyewear are designed for various tasks. Safety goggles provide a snug seal against the face, blocking debris more effectively than safety glasses, making them ideal for dusty tasks or liquid splashes. It’s important to choose eyewear that complies with the ANSI Z87.1 standards for safety. Failing to wear appropriate protection can lead to severe injuries, long-term vision damage, or even permanent blindness.

Hearing Protection: Preserve Your Hearing

Using loud power tools without adequate hearing protection can lead to permanent noise-induced hearing loss. Prolonged exposure to sounds exceeding 85 decibels—common in many power tools—can significantly damage your hearing over time. Fortunately, various types of hearing protection are available.

- Earplugs: These small devices can reduce noise levels by about 15-30 decibels depending on the material and design. Some types even include filters that allow for safer sound frequencies while blocking harmful noise levels.

- Earmuffs: Designed to fit over the entire ear, they offer better noise reduction and comfort. Passive earmuffs can reduce noise up to 30 decibels, while electronic versions amplify low-level sounds, enhancing communication.

- Combination Systems: In high noise environments, combining earplugs and earmuffs maximizes protection.

When selecting hearing protection, consider the Noise Reduction Rating (NRR), which assesses the effectiveness of the device against loud sounds. Always prioritize hearing safety in your projects to prevent irreversible hearing damage.

Respiratory Protection: Breathe Easy

It is essential to wear appropriate respiratory protection when using power tools to safeguard against harmful dust and fumes. The types of respiratory protection vary based on specific hazards, including airborne particles and chemical vapors.

- N95 Respirators: Ideal for filtering out solid particles like wood dust and metal fumes.

- P100 Respirators: Capture 99.97% of airborne particles, necessary for dealing with toxic substances.

- Half-Mask or Full-Face Respirators: Provide protection against both dust and chemicals, with full-face masks also protecting the eyes.

- Powered Air-Purifying Respirators (PAPRs): Battery-powered masks suitable for prolonged use in high contaminant environments.

Regularly inspect and maintain your respiratory gear for effectiveness, and consider general safety practices such as proper ventilation and dust extraction systems to ensure workplace safety [Source: One Power Tool Safety Tips].

Hand Protection: Secure Your Hands

Choosing the right gloves for working with power tools is essential for preventing cuts, abrasions, and injuries. Materials like Kevlar or steel mesh can significantly reduce the risk of cuts, while padded gloves can help absorb impacts from repetitive motions. The wrong choice can expose your hands to hazardous conditions.

Ensure that gloves fit well to enhance dexterity and reduce snag hazards [Source: OCR]. Look for gloves with additional features like grip enhancements, which help maintain control over tools. Factors to consider include the material’s durability, resistance to abrasions, and specific hazards encountered during your projects [Source: OSHA].

Foot Protection: Guard Your Feet

Working with heavy tools requires the right footwear to protect against falling objects and various hazards. Key types of protective footwear to consider include:

- Steel-Toed Boots: Essential for those exposed to heavy machinery, protecting against impacts.

- Composite-Toe Boots: Lightweight alternatives offering the same level of protection without the weight. They are ideal for all-day wear.

- Metatarsal Guards: Provide extra protection against heavy items dropping, crucial in settings with sharp tools.

- Slip-Resistant Soles: Help prevent falls in slippery conditions.

- Waterproof Options: Essential for keeping feet dry in wet conditions

Selecting appropriate footwear significantly reduces the risk of foot injuries while enhancing comfort. For further tips on foot safety in work environments, check out our articles on safety practices.

Proper Clothing: Dress for Safety

Selecting the right clothing while working with power tools is crucial for safety. Follow these best practices:

- Dress in Layers: Lightweight, breathable fabrics are preferable for ease of movement and protection.

- Avoid Loose Clothing: Loose garments can catch in machinery, leading to entanglement.

- Choose the Right Fabric: Thick cotton or denim offers protection against cuts and abrasions.

- Use Protective Gear: Complement clothing with appropriate PPE for better protection.

- Avoid Accessories: Minimize jewelry or ties that could catch on equipment.

- Utilize High-Visibility Clothing: Improves safety in low-light conditions.

By following these guidelines, you enhance your safety while engaging with power tools. For more insights, check our guide on essential power tool safety measures.

Dust Extraction: Maintain Clean Workspaces

Effective dust extraction systems are crucial for maintaining clean work environments. They minimize airborne dust particles that pose serious health risks, such as respiratory diseases [Source: ResearchGate]. Implementing effective dust extraction enhances workplace safety and productivity.

Organizations must adhere to regulations regarding air quality standards to avoid severe penalties. Investing in robust dust extraction systems safeguards employee health while promoting a culture of safety [Source: Health and Safety at Work].

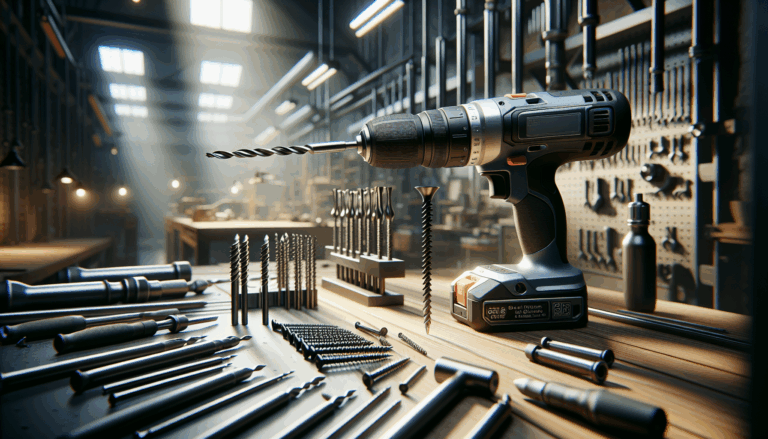

Safety Guards and Devices: Implement Safety Measures

Safety guards and devices play an essential role in ensuring safe usage of power tools:

- Blade Guards: Shield the blade on circular saws when not in use.

- Emergency Stop Switches: Allow quick stops during emergencies to reduce injury risk.

- Antikickback Mechanisms: Prevent material from being forcefully ejected back towards the operator.

- Personal Protective Equipment (PPE): Includes goggles, gloves, and ear protection to mitigate injury risks.

- Zero Voltage Release Switches: Ensures power tools do not restart automatically after power interruptions.

These devices are designed to not only protect users but also enhance the overall effectiveness of tools during operation.

Sources

- American Optometric Association – Why Eye Protection is Necessary

- ResearchGate – Importance of Dust Extraction in Workplaces

- Health and Safety at Work – Dust Control Solutions

- CDC – Noise Induced Hearing Loss

- CDC – N95 Respirator Factsheet

- OSHA – Eye and Face Protection Standards

- OSHA – Personal Protective Equipment

- CDC – Powered Air-Purifying Respirators

- NCBI – Metatarsal Guards for Foot Protection

- Safety Network – Importance of Eye Protection in the Workplace

- One Power Tool – Essential Power Tool Safety Measures

- One Power Tool – Safety Tips for Using an Electric Hammer Drill